July 24, 2024

Are Polycarbonate Sheets Flexible?

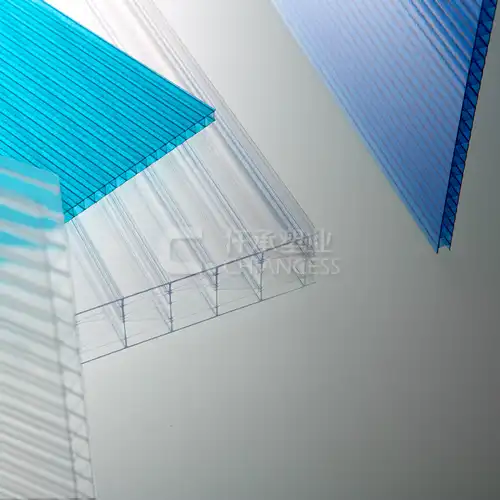

Sheets made of polycarbonate are renowned for their exceptional adaptability and adaptability to a wide range of applications. They are highly adaptable for curved installations and custom designs that other materials may struggle to accommodate due to their ability to bend without breaking. Polycarbonate sheets are safer and simpler to handle during transportation and installation than conventional glass because they are significantly lighter while maintaining an impressive impact resistance.The products frequently outperform glass and other plastics in terms of transparency. Their exceptional optical clarity enables maximum light transmission while minimizing glare. They are ideal for skylights, greenhouse panels, and architectural glazing, all of which require natural light without sacrificing durability, due to this property.they can be used as safety shields and protective barriers in harsh environments like construction sites due to their durability.

In outdoor applications like awnings, signage, and pool enclosures, their long-term performance is ensured by their resistance to UV radiation and weathering.Additionally, they are valued for their adaptability and ease of manufacture. They are simple to cut, drill, and thermoform into intricate shapes, making it possible for architects and designers to realize novel ideas and distinctive architectural features.In conclusion, polycarbonate sheets are essential for a wide range of industries and applications due to their transparency, durability, and flexibility. These adaptable materials continue to redefine possibilities in construction, manufacturing, and other fields, whether they do so by increasing safety, decreasing energy consumption, or facilitating innovative design solutions.

How Flexible Are Polycarbonate Sheets?

Polycarbonate sheets are highly flexible, making them a popular choice in many industries. This flexibility stems from the molecular structure of polycarbonate, which allows it to bend without cracking or breaking. This property is particularly advantageous in construction and manufacturing, where materials often need to be molded or shaped into complex forms.

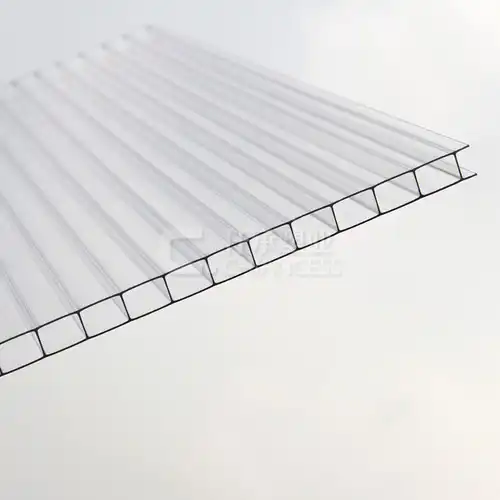

One of the primary factors influencing the flexibility of the products is their thickness. Thinner sheets are more pliable and can be bent at room temperature without the risk of damage. For instance, sheets that are around 1/8 inch thick can be easily manipulated into various shapes, making them ideal for applications like curved windows, skylights, and other architectural features. Even thicker sheets, though less flexible, still offer significant versatility compared to glass or acrylic.

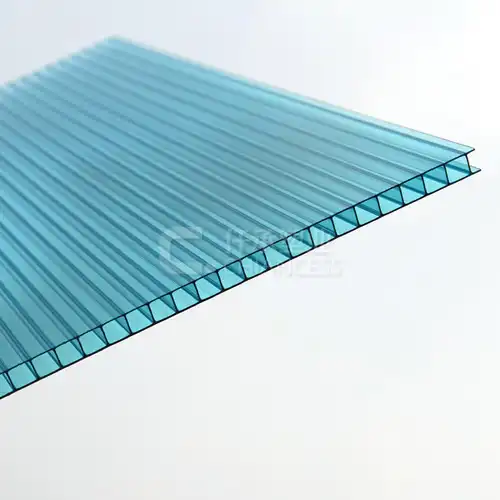

Another aspect contributing to their flexibility is the type of polycarbonate. Multiwall and corrugated , for example, are designed with a structure that enhances their flexibility while maintaining strength. These types are often used in roofing and greenhouse applications, where bending to fit specific shapes is necessary.

In practical applications, the flexibility of polycarbonate sheets allows for cold bending, meaning they can be shaped without the need for heat treatment. This characteristic simplifies the installation process, reducing both time and cost. Additionally, polycarbonate's flexibility combined with its impact resistance makes it a safer alternative to glass, which can shatter under stress.

What Are the Benefits of Polycarbonate Sheets Compared to Other Materials?

When comparing polycarbonate sheets to other materials like glass and acrylic, several benefits stand out:

-

Impact Resistance: Polycarbonate is significantly more impact-resistant than both glass and acrylic. It is 250 times stronger than glass and 30 times stronger than acrylic, making it suitable for applications where durability is crucial, such as in protective barriers and safety shields.

-

Weight: Polycarbonate is much lighter than glass, which makes it easier to handle and install. This reduction in weight also means less structural support is needed, potentially lowering construction costs.

-

Transparency: While both glass and acrylic offer high levels of transparency, polycarbonate provides excellent light transmission while also being less prone to shattering. This makes it ideal for applications like greenhouse panels and skylights, where clarity and safety are both important.

-

UV Protection: Many polycarbonate sheets are treated with UV-resistant coatings, which protect against the harmful effects of UV rays. This makes them a better choice for outdoor applications where long-term exposure to sunlight could degrade other materials.

-

Ease of Fabrication: Polycarbonate can be easily cut, drilled, and shaped using standard tools. This ease of fabrication makes it a versatile material for a wide range of applications, from DIY projects to large-scale industrial uses.

-

Insulation: Polycarbonate provides better thermal insulation compared to glass. This property is particularly beneficial in applications like greenhouses and conservatories, where maintaining a stable internal temperature is essential.

What Are the Common Uses of Polycarbonate Sheets?

The versatility and robustness of polycarbonate sheets make them suitable for a variety of applications across different industries:

-

Construction: In the construction industry, products are used for roofing, skylights, and glazing. Their flexibility allows them to be shaped into curves and unique designs, providing architects with creative freedom while ensuring durability and safety.

-

Greenhouses: Polycarbonate is a popular choice for greenhouse panels due to its high light transmission and UV protection. The material helps create an optimal growing environment by allowing sunlight to penetrate while protecting plants from harmful UV rays and impact damage from hail.

-

Safety and Security: Due to its high impact resistance, polycarbonate is often used in applications requiring security and protection, such as in riot shields, bulletproof windows, and machine guards. Its ability to withstand significant force without breaking makes it an ideal material for these uses.

-

Automotive: In the automotive industry, polycarbonate is used for headlight lenses, windshields, and interior components. Its lightweight nature helps improve fuel efficiency, while its durability enhances safety.

-

Electronics: Polycarbonate's electrical insulation properties make it suitable for use in electronic devices, where it is used for components like enclosures, connectors, and circuit boards.

-

Signage: The material's durability and ease of fabrication make it a popular choice for both indoor and outdoor signage. Polycarbonate signs are resistant to weathering, impact, and UV exposure, ensuring longevity and clarity over time.

Conclusion

Polycarbonate sheets are a highly flexible, durable, and versatile material that outperforms many alternatives like glass and acrylic in various applications. Their flexibility, combined with impact resistance, UV protection, and ease of fabrication, makes them ideal for a wide range of uses, from construction and greenhouses to safety equipment and electronics.

If you are interested in our products, you can contact us at: simon@chiancess.com.

References

- Laird Plastics - The Complete Guide to Polycarbonate Sheets

- Acme Plastics - Polycarbonate Sheets: In Stock & Ready to Ship

- Simply Plastics - The ultimate guide to Polycarbonate

- Piedmont Plastics - Polycarbonate Panels: Strength, Flexibility, and Cost-Effective

- Storm Building Products - What Is Polycarbonate Sheet? Everything You Need To Know

- Danpal - Polycarbonate Sheets: The Ultimate Building Material

- Polycarbonatesheet.com - What are polycarbonate sheets? A complete guide to choosing the best sheets!

- RTPrototype.com - Polycarbonate (PC): Definition, Properties, Colors and Uses

- Cope Plastics - Polycarbonate Sheets | Impact Resistance & Clarity

- TAP Plastics - Custom Polycarbonate Sheets Cut to Size

.webp)