July 2, 2024

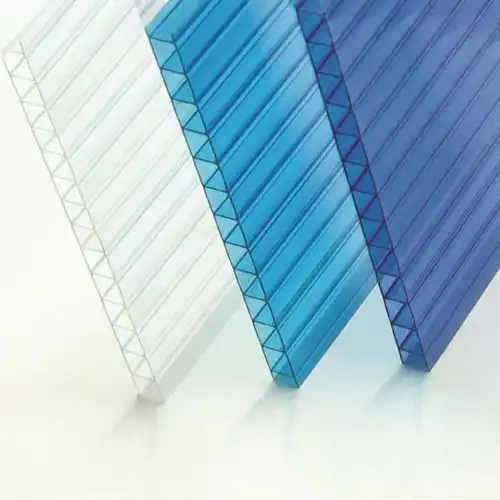

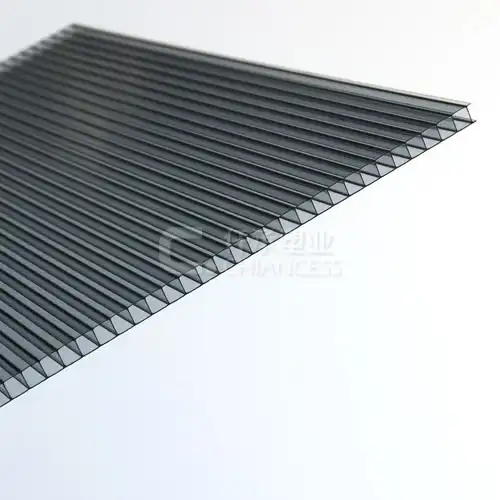

Polycarbonate (PC) is a versatile, durable thermoplastic polymer commonly used in various industries, including automotive, construction, and electronics. Known for its tall affect resistance, straightforwardness, and fabulous warm properties, polycarbonate has ended up a prevalent choice for various applications.One question that often arises is whether polycarbonate can be colored.In this article, I will investigate the conceivable outcomes and strategies of coloured solid polycarbonate sheet, the points of interest of doing so, and the applications of colored polycarbonate.

Methods of Coloring Polycarbonate

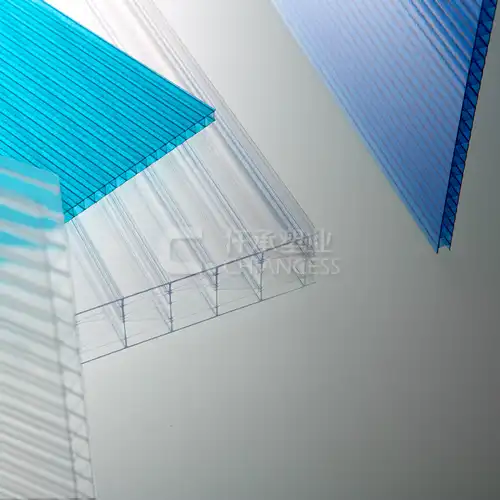

Polycarbonate sheets can be colored through various methods, each offering unique advantages depending on the application requirements. Here are some common methods used to color polycarbonate:

Masterbatch Coloring: One of the most common strategies of coloring polycarbonate is through the utilization of masterbatch. A masterbatch is a concentrated blend of shades and added substances typified amid a warm handle into a carrier tar, which is at that point cooled and cut into granules. These granules can be included to common colored polycarbonate sheets amid the expulsion or molding handle to accomplish the craved color. The masterbatch strategy permits for exact color coordination and consistency, making it perfect for applications where consistency is basic.

Liquid Colorants: Another method to coloured polycarbonate sheet is by using liquid colorants. Liquid colorants are added to the polycarbonate resin during processing, offering the advantage of quick color changes and reduced waste compared to solid masterbatch granules. This method is particularly useful in applications requiring frequent color changes or smaller production runs. Liquid colorants also allow for more vibrant and intense colors, enhancing the aesthetic appeal of the final product.

Surface Coating: In expansion to joining color amid the fabricating handle, polycarbonate can moreover be colored through surface coating techniques. This includes applying a colored coating to the surface of the coloured solid polycarbonate sheet or portion. Surface coating can give extra benefits such as UV security, scratch resistance, and improved durability. This strategy is frequently utilized in applications where the colored surface is subjected to unforgiving natural conditions or where a particular wrap up, such as gleam or matte, is craved.

What are the Benefits of Coloring Polycarbonate?

Coloring polycarbonate offers several benefits that enhance its performance and visual appeal in various applications:

Aesthetic Appeal: Coloring polycarbonate allows for customization to match specific aesthetic requirements. Whether for architectural design, automotive applications, or signage, colored polycarbonate can enhance the visual appeal of the finished product.

UV Protection: Colored polycarbonate sheets often include UV protection as part of their coloring process. This UV protection helps prevent yellowing and degradation of the material when exposed to sunlight, extending the lifespan of the sheets.

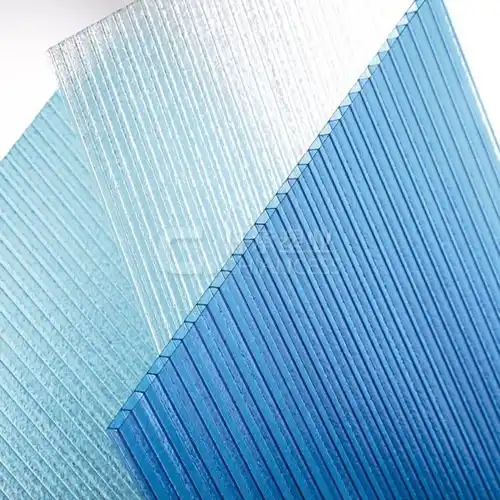

Light Transmission Control: By selecting the appropriate color or tint, polycarbonate sheets can control the amount of light transmission. This is particularly useful in applications such as skylights or greenhouse roofing, where different light transmission levels are required.

Durability and Impact Resistance: Colored polycarbonate retains the inherent durability and impact resistance of clear polycarbonate sheets. This makes it suitable for applications where strength and safety are paramount, such as in safety barriers or machine guards.

What are the Applications of Colored Polycarbonate?

The car industry broadly employments colored polycarbonate for different applications. Colored polycarbonate is utilized for insides components such as dashboards, entryway boards, and trim pieces. Its lightweight and tough properties make it an fabulous choice for these applications, and the capacity to customize the color guarantees a cohesive and engaging insides plan. Furthermore, colored polycarbonate is utilized for outside lighting components, such as headlights and taillights, where color and straightforwardness are basic.

In the development industry, colored polycarbonate is utilized for material, cladding, and coating applications. Its tall affect resistance and UV soundness make it an perfect fabric for these applications, whereas the capacity to select diverse colors permits for inventive and useful building plans. Colored polycarbonate boards can too be utilized for signage and segments, giving both tasteful and useful benefits.

Colored polycarbonate is broadly utilized in the customer gadgets industry for items such as smartphones, tablets, and gaming consoles. The capacity to accomplish dynamic and reliable colors improves the visual request of these items, making them more alluring to consumers. Additionally, the toughness and lightweight nature of polycarbonate make it an perfect fabric for defensive cases and covers.

In the medical field, coloured solid polycarbonate sheet is used for various devices and components. The ability to color-code medical devices helps in identifying and distinguishing between different tools and instruments, reducing the risk of errors during medical procedures. Colored polycarbonate is also used in the production of medical housings and casings, where both aesthetics and durability are important.

Conclusion

In conclusion, polycarbonate can indeed be colored using various methods such as masterbatch coloring, liquid colorants, and surface coating. Each strategy offers interesting points of interest, permitting for the creation of stylishly satisfying, useful, and strong products. Colored polycarbonate finds applications in various businesses, counting car, development, shopper hardware, and therapeutic gadgets, highlighting its flexibility and offer.By understanding the methods and benefits of coloring polycarbonate, manufacturers can leverage this material to enhance their products and meet the diverse needs of their customers.

For more information about polycarbonate and its applications, feel free to contact us at simon@chiancess.com.

References

ABC Roofing Supplies. (2023). Guide to Installing Polycarbonate Roofing Sheets. Retrieved from https://www.abcroofingsupplies.com/installing-polycarbonate-roofing-sheetsPalram Americas. (2023). Palram Installation Instructions. Retrieved from https://www.palramamericas.com/us/products/polycarbonate-sheets/

Suntuf. (2023). How to Install Polycarbonate Roofing Sheets. Retrieved from https://www.suntuf.com/au/how-to-install-polycarbonate-roofing-sheets

The Plastic People. (2023). How to Install Polycarbonate Roofing Sheets. Retrieved from https://www.theplasticpeople.co.uk/blog/how-to-install-polycarbonate-roofing-sheets/

Greenhouse Stores. (2023). How to Install Polycarbonate Sheets in Your Greenhouse. Retrieved from

.webp)