July 24, 2024

How Are Polycarbonate Sheets Made?

Polycarbonate sheets are long-lasting and suitable for many uses. They are great for development and hardware applications because they are easy to use, protect against impact, and are strong. This blog post looks at how the products are made. We will also answer questions about them.

What Are the Benefits of Using Polycarbonate Sheets?

Polycarbonate sheets are the best because they are adaptable, affordable, durable, and safe. They are used in many different ways because they are strong and can be used with many other materials. They are also affordable, which makes them popular with designers, manufacturers and builders.

Durability and Strength

Well-known for their exceptional strength and durability. Due to their superior impact resistance over glass glass and numerous other polymers, they are practically indestructible. As a result, they are ideal for applications requiring dependability and safety. The products, for instance, are frequently used to construct safety windows, obstacles to safety, and eyeglass lenses.

Safety and Security

Polycarbonate sheets excel in safety applications due to their superior resistance to impact compared to glass, which can shatter into sharp fragments upon impact. Polycarbonate sheets are ideal for use as safety glazing in schools, hospitals, and other public buildings where protection against breakage and injury is essential due to this property. Their capacity to withstand impact without breaking enhances safety and peace of mind in sensitive settings.

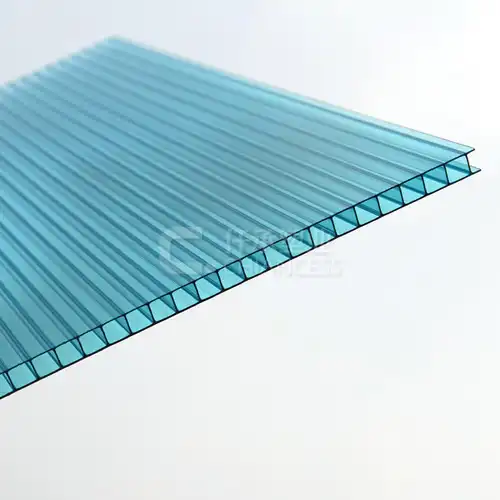

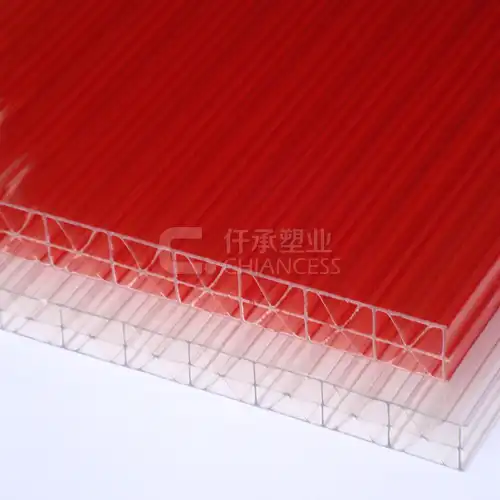

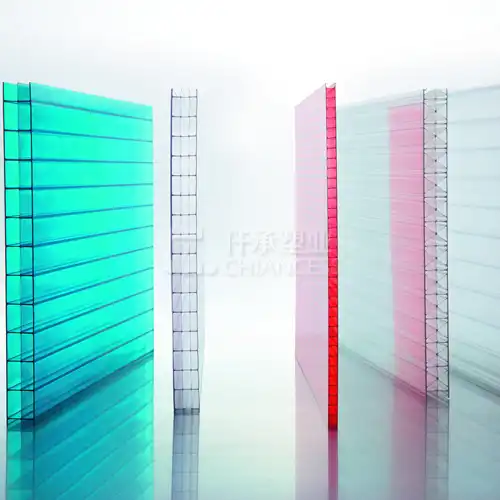

Versatility and Customization

Polycarbonate sheets are very adaptable and simple to modify to meet a variety of requirements. They can be used for a wide range of tasks because they come in a variety of thicknesses, colors, and surface textures. For windows and light diffusers, for instance, clear the products are used, whereas tinted or frosted sheets are used for privacy panels and decorative elements.

they can also be used to easily create intricate shapes. Due to their adaptability, they are suitable for use in electronics and automotive industries that require precise and intricate designs.

Cost-Effectiveness

cost more than other materials like acrylic or glass, but they save money in the long run because they last a long time and don't need much maintenance. They last a long time, so replacing them will save you money.

are also easy to transport and install. They save money on labour costs during installation and maintenance.

How Are Polycarbonate Sheets Manufactured?

The manufacturing process for them includes the raw material preparation, extrusion, and finishing processes. Each stage of the production process will be discussed in detail here.

Raw Materials and Preparation

Polycarbonate sheets are made from polycarbonate resin. BPA and phosgene make up this resin. They combine to form long chains of polycarbonate during the polymerisation process. The resulting resin is an excellent impact-resistant thermoplastic that is transparent.

The polycarbonate resin is dried before extrusion. Moisture can cause flaws in the finished product, so this is important. To improve its properties, the dried resin is melted and mixed with additives like colourants, UV stabilisers and flame retardants.

Extrusion Process

The manufacturing of polycarbonate sheets begins with the extrusion procedure. Making a continuous sheet requires melting the prepared resin and forcing it through a die. The key steps in the extrusion process are as follows::

-

Combining and Melting: The heated and melted dried resin is fed into an extruder. To ensure uniformity and enhance the desired properties of the finished sheet, additives are mixed with the molten resin.

-

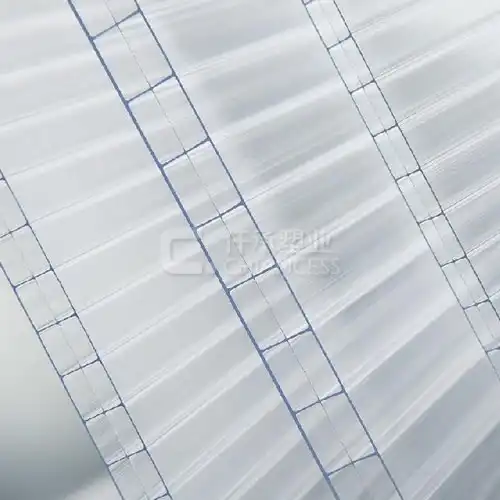

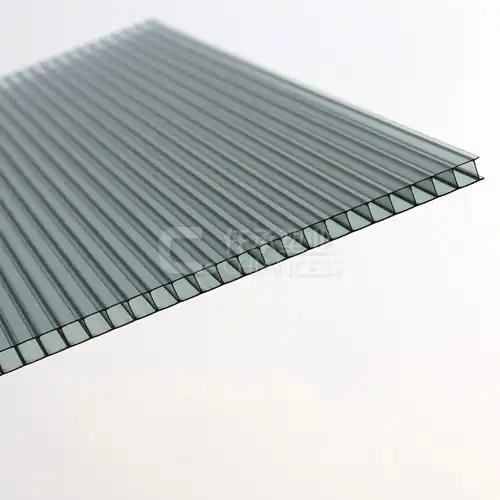

Extrusion: A die is used to force the molten resin through, resulting in a flat sheet. The gap of the die and the extruder's speed can be adjusted to control the sheet's thickness.

-

Calendaring and cooling: Using a series of rollers, the extruded sheet is immediately cooled and solidified. Calendering is the process of making sure the sheet has a smooth and even surface.

-

Trimming and Cutting: The sheet is trimmed to remove any excess material and cut to the desired length after it has cooled. For a neat finish, the edges are smoothed.

Finishing and Quality Control

The final stage of the manufacturing process includes finishing and quality control. The are finished in a number of ways, including:

-

Care for the Surface: The sheets' surface may be treated to enhance their properties, depending on the application. To increase durability, for instance, an anti-scratch coating or a UV protective layer can be added to protect against sunlight degradation.

-

Quality Control: Defects such as bubbles, cracks, or discoloration are looked for on each sheet. To ensure that only high-quality products reach the market, any defective sheets are rejected.

-

Distribution and packaging: To safeguard the finished sheets during transportation and storage, they are packaged. After that, they are sold to a wide range of customers and businesses for use in a wide range of tasks.

Are Polycarbonate Sheets Safe for the Environment?

Polycarbonate sheets are not an exception when it comes to environmental safety. We'll take a look at how the products affect the environment in this section, as well as how long they last and how easily they can be recycled.

Recyclability

The fact that polycarbonate sheets can be recycled is one of their environmental benefits. Thermoplastic polycarbonate can be repeatedly melted down and reformed without significantly affecting its properties. As a result, it is an excellent recycling candidate.

Polycarbonate that has been recycled can be used to make new sheets, reducing waste and the need for new raw materials. Before being melted and re-extruded into new sheets, used polycarbonate products are collected, cleaned, and shrunk into small pieces as part of the recycling process.

Longevity and Durability

Polycarbonate sheets have a positive impact on the environment because they last a long time. They are more durable and resistant to damage than many other materials. This means that fewer replacement materials are needed, which has a smaller impact on the environment. Polycarbonate products have a smaller environmental impact because they last longer.

Energy Efficiency

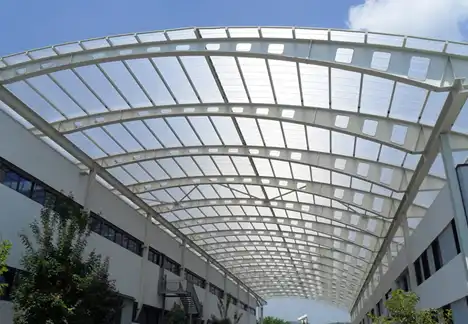

Sheets made of polycarbonate help save energy in a variety of applications. For instance, because of their high transparency and ability to diffuse light, they are ideal for use in skylights and greenhouses because they make it possible for natural light to enter while reducing the need for artificial lighting. Buildings may see significant energy savings as a result.

Additionally, the insulation properties of sheets aid in maintaining buildings' temperature stability, reducing the need for heating and cooling. As a result, both energy consumption and carbon emissions are reduced.

Responsible Production

Many manufacturers want to make sheets in an environmentally friendly way. They use energy-saving methods, reduce waste and use recycled materials.

Challenges and Considerations

The product offer several environmental benefits, but it's important to weigh the drawbacks as well. The use of BPA in the production of polycarbonate resin has raised concerns about its impact on the environment and health. However, when polycarbonate products are manufactured and used correctly, they don't pose significant risks.

Both consumers and manufacturers need to handle and dispose of sheets responsibly. Implementing recycling programs and initiatives can help minimize the environmental impact of polycarbonate products by encouraging their reuse and repurposing, thereby preventing them from ending up in landfills.

Conclusion

They are a remarkable material with numerous applications and benefits. Due to their exceptional strength, durability, and adaptability, they are popular in the automotive, electronics, and construction industries. In order to produce sheets of high quality that meet stringent requirements, careful steps in the manufacturing process include preparation, extrusion, and finishing.

In addition to their practical advantages, they have significant environmental benefits. They are recyclable, energy efficient, and long-lasting, all of which contribute to a more sustainable future. As we continue to place an emphasis on environmental responsibility, they will play a crucial role in a variety of applications, assisting in resource conservation and waste reduction.

If you are interested in our products, you can contact us at: simon@chiancess.com

References

"Polycarbonate: A Versatile and Durable Material." Polycarbonate Sheets Info, polycarbonatesheetsinfo.com.

"The Manufacturing Process of Polycarbonate Sheets." PC Sheets Manufacturing, pcsheetsmanufacturing.com.

"Benefits of Polycarbonate Sheets." Construction Materials Online, constructionmaterialsonline.com.

"Environmental Impact of Polycarbonate." Green Building Materials, greenbuildingmaterials.com.

"Recycling Polycarbonate Sheets." Sustainable Plastics, sustainableplastics.com.

"Applications of Polycarbonate Sheets." Industry Applications Journal, industryapplicationsjournal.com.

.webp)