May 18, 2024

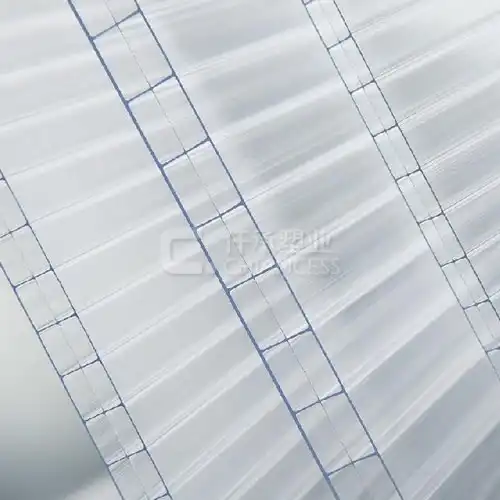

In the realm of construction materials, the debate between polycarbonate hollow sheets and traditional glass has been ongoing. Both materials offer unique advantages and drawbacks, leaving builders and architects pondering which option best suits their needs. In this article, we'll dive into the comparison between polycarbonate empty sheets and glass, looking at their properties, applications, and the contemplations to keep in intellect when choosing between the two.

Why are polycarbonate hollow sheets gaining popularity in construction?

They are gaining popularity in construction due to their versatility, durability, and performance benefits. Their lightweight yet strong composition makes them easy to work with and resistant to impact, weathering, and UV radiation. Additionally, their ability to transmit diffused natural light while providing insulation and soundproofing contributes to energy efficiency and comfort in buildings. Architects and builders appreciate their flexibility in design and wide range of applications, making them an increasingly preferred choice in modern construction projects.

Polcarboynate empty sheets have been relentlessly picking up footing in the development industry for a few reasons. One of the essential variables driving this ubiquity is their remarkable toughness. Not at all like glass, which can smash upon affect, polycarbonate sheets are profoundly safe to breakage. This versatility makes them an appealing choice for applications where security and life span are vital.

Additionally, polycarbonate hollow sheets are lightweight yet robust, making them easier to handle and install compared to glass. This characteristic not only simplifies the construction process but also reduces transportation costs and the risk of breakage during handling.

Furthermore, polycarbonate sheets offer superior thermal insulation properties compared to glass. This capacity to control temperature can lead to vitality investment funds in buildings by decreasing warming and cooling costs. As sustainability becomes an increasingly important consideration in construction, the energy-efficient nature of it positions them as a favorable choice for environmentally conscious projects.

How do the properties of polycarbonate hollow sheets compare to glass?

While contrasting polycarbonate empty sheets with glass, a few key properties become an integral factor: Strength: Polycarbonate sheets ultimately depend on multiple times more grounded than glass of similar thickness, making them profoundly impervious to effect and defacing. Transparency: Though the two materials offer straightforwardness, glass will in general have way better optical lucidity. Nevertheless, movements in polycarbonate development have headed to pushed ahead straightforwardness, making it a sensible elective to glass in various applications. Weight: Polycarbonate sheets are basically lighter than glass, making them less requesting to ship, handle, and present. Insulation: Polycarbonate empty sheets give preferred warm protection over glass, assisting with controlling indoor temperatures and decrease energy utilization. Cost: As a rule, polycarbonate sheets are more financially savvy than glass, both as far as material costs and establishment costs.

What are the practical applications of polycarbonate hollow sheets in construction?

The sheets find a multitude of practical applications in construction due to their versatility, durability, and lightweight properties. One key application is in roofing systems, where these sheets offer excellent impact resistance, UV protection, and weatherproofing capabilities.

They are commonly used in skylights, canopies, and greenhouse roofs, allowing natural light to penetrate while providing insulation and protection from the elements.

In addition to roofing, they are popular for creating translucent partitions and walls in both interior and exterior spaces. Their translucency diffuses light, creating visually appealing environments while offering privacy and sound insulation. These sheets are also used in architectural features such as facades, where their ability to be molded into various shapes and colors allows for innovative and eye-catching designs.

Moreover,they are favored for their strength-to-weight ratio, making them suitable for applications requiring lightweight yet durable materials. They are commonly used in pergolas, carports, and awnings, providing shelter and shade without adding excessive weight to structures. Their impact resistance makes them an ideal choice for safety glazing in areas prone to breakage, such as sports facilities and public buildings.

Furthermore, polycarbonate hollow sheets are valued for their thermal insulation properties, contributing to energy efficiency in buildings. They can be used as cladding material, helping to regulate interior temperatures by minimizing heat transfer and reducing reliance on artificial heating and cooling systems.

Overall, the practical applications of it in construction are extensive and diverse. From roofing to partitioning, from facades to safety glazing, these versatile materials offer architects and builders a wide range of solutions to meet various design requirements while enhancing aesthetics, durability, and energy efficiency in construction projects.

The sheets find diverse applications in construction, ranging from roofing and skylights to partitions and façades. Their versatility and durability make them suitable for both residential and commercial projects.

Roofing: Polycarbonate sheets are commonly used for roofing applications due to their lightweight nature, durability, and excellent weather resistance.

They can withstand harsh environmental conditions, including hail, wind, and UV radiation, making them ideal for outdoor structures such as pergolas, canopies, and greenhouse roofs.

Skylights: The transparency of it makes them well-suited for skylights, allowing natural light to illuminate interior spaces while providing thermal insulation and UV protection. This combination of aesthetics and functionality enhances the overall appeal and energy efficiency of buildings.

Partitions and Façades: In modern architecture, polycarbonate sheets are increasingly being used for interior partitions and façades. Their versatility in terms of color, texture, and transparency allows designers to create visually striking elements while maintaining functionality and practicality.

Conclusion

In conclusion, while glass has long been a staple in construction, polycarbonate hollow sheets offer a compelling alternative with their superior durability, thermal insulation, and cost-effectiveness. As the construction industry continues to evolve, incorporating innovative materials like polycarbonate becomes essential for meeting the demands of sustainability, safety, and efficiency in building design and construction.

If you are interested in our products, you can contact us at: simon@chiancess.com

References

- "Polycarbonate Sheet - A Complete Guide" - Tuflite Polymers

- "Polycarbonate vs. Glass: Comparing Properties" - A&C Plastics

- "Polycarbonate Roofing Sheets: Pros & Cons" - Roofing Megastore

- "The Benefits of Polycarbonate Roofing Sheets" - Ariel Plastics

- "The Advantages of Polycarbonate Hollow Sheets" - Sundely

- "Why Polycarbonate Hollow Sheets are the Future of Construction" - Plastics for Africa

- "The Advantages and Disadvantages of Polycarbonate Sheets" - Tuflite Polymers

.webp)