July 12, 2024

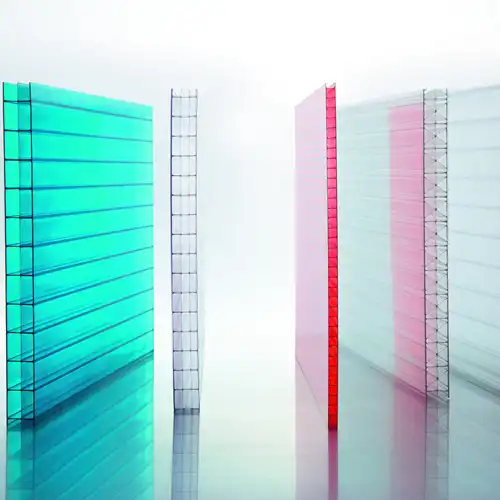

Empty polycarbonate sheets have become progressively famous in different businesses because of their excellent properties and various applications. One of the many questions that people ask is how long these sheets last and what makes them so durable.

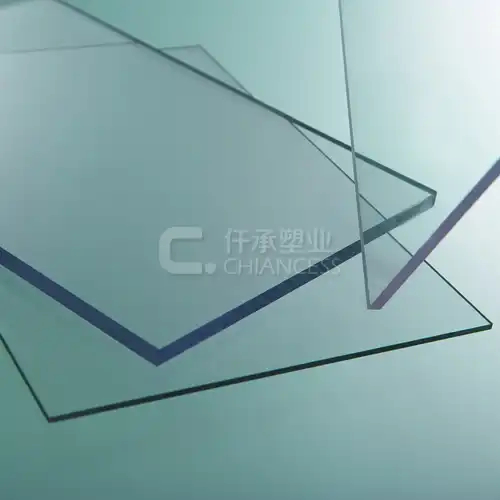

To begin, the material's durability is significantly influenced by its inherent strength. It is known to be a lot more grounded than materials like glass and has a high effect obstruction that prevents it from earning back the original investment with a great deal of power. As it is being developed for inlet windows, material, and protective barriers, this makes it ideal for applications where prosperity and life expectancy are crucial.

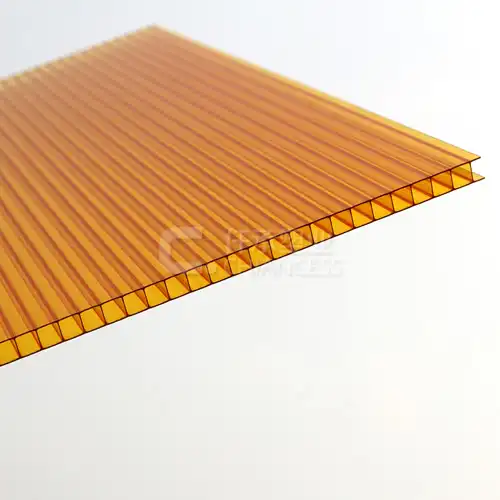

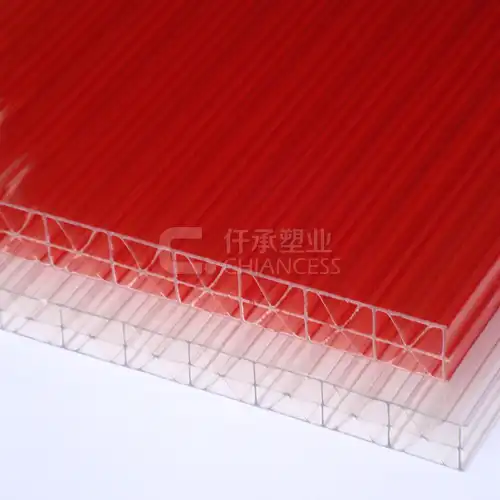

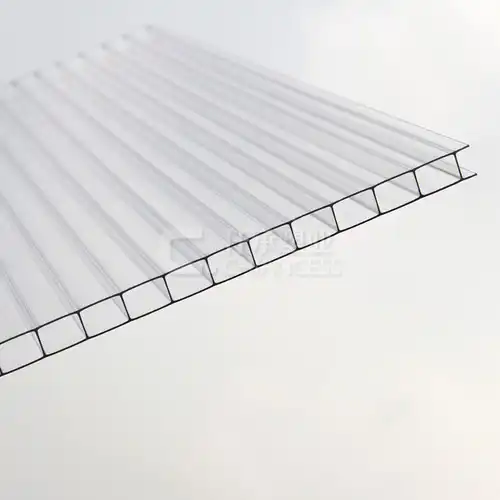

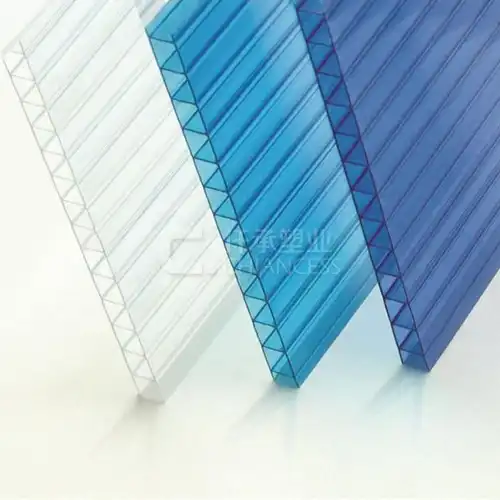

Additionally, the structure of hollow polycarbonate sheets makes them more long-lasting. The development with twin or different walls not just gives protection properties that are helpful in various conditions yet additionally increments strength. By evenly distributing stress across the sheet and reducing the likelihood of impact damage, this design lowers the risk of cracking or fracturing.

Also, polycarbonate is incredibly impervious to enduring. It is normally impervious to bright light, keeping its optical clearness and tasteful allure over the long run while keeping it from yellowing or weakening. Applications outdoors where there is constant sunlight exposure necessitate this UV resistance.

Additionally, hollow polycarbonate sheets' practical durability is enhanced by their lightweight nature. They are less likely to be damaged during installation or maintenance because they are simpler to transport, install, and handle than heavier materials like glass or metal.

In conclusion, the inherent strength, distinctive structural design, weather resistance, and practical handling characteristics of the sheets make them long-lasting. These qualities not only ensure their dependability under testing conditions, but they also contribute to their widespread acceptance across a variety of projects, including consumer goods and cutting-edge applications for design and development.

What Makes Hollow Polycarbonate Sheets Durable?

Hollow polycarbonate sheets are renowned for their durability, which stems from several key factors. Firstly, polycarbonate itself is an incredibly strong material, known to be impact-resistant and virtually unbreakable. This makes it ideal for applications where toughness is paramount, such as in construction and automotive industries. The hollow structure of these sheets further enhances their strength-to-weight ratio, providing structural integrity without adding unnecessary weight.

To understand their durability, it's essential to look at the manufacturing process. Hollow polycarbonate sheets are typically produced through an extrusion process that creates a series of interconnected chambers or cells within the sheet. These chambers not only reduce weight but also contribute to the overall strength of the sheet by distributing impact forces across a larger surface area.

Moreover, the UV resistance of polycarbonate is another factor that adds to its durability. Many high-quality sheets are coated with UV protectants during manufacturing, which helps prevent yellowing and degradation when exposed to sunlight over time. This UV protection is crucial for outdoor applications where prolonged exposure to the elements could otherwise compromise the material's integrity.

How Do Hollow Polycarbonate Sheets Perform in Different Environments?

The performance of hollow polycarbonate sheets can vary depending on the environment in which they are used. Generally, these sheets are designed to withstand a wide range of conditions, but understanding their limitations is key to ensuring longevity and performance.

In indoor environments, such as in skylights or partition walls, hollow polycarbonate sheets excel due to their lightweight nature and ease of installation. They provide excellent light transmission while maintaining a strong barrier against impacts and structural stresses. However, factors like temperature fluctuations and chemical exposure can still affect their long-term performance if not properly considered during installation.

For outdoor applications, such as in roofing or greenhouse panels, hollow polycarbonate sheets are often subjected to more extreme conditions. UV radiation, fluctuating temperatures, high winds, and hail are all environmental factors that can impact durability. High-quality sheets with enhanced UV protection and weather-resistant coatings are recommended for such applications to mitigate these effects and prolong service life.

Installation and maintenance also play crucial roles in ensuring the durability of hollow polycarbonate sheets. Proper sealing and framing techniques help prevent water ingress and reduce the risk of damage from environmental factors. Regular cleaning and inspection are also recommended to remove debris and inspect for any signs of wear or damage that could compromise the sheet's integrity over time.

What Factors Can Affect the Durability of Hollow Polycarbonate?

Several factors can influence the durability of hollow polycarbonate sheets, ranging from material quality to installation techniques and environmental conditions. Understanding these factors is crucial for making informed decisions about their use and maintenance.

-

Material Quality: The quality of the polycarbonate resin used in manufacturing plays a critical role in determining the durability of the sheets. High-quality resins with consistent properties ensure better impact resistance, UV stability, and overall longevity. Cheaper alternatives or recycled materials may compromise these qualities, leading to premature degradation.

-

UV Protection: UV radiation is one of the primary factors that can degrade polycarbonate over time, causing yellowing, brittleness, and loss of impact resistance. Quality hollow polycarbonate sheets are treated with UV stabilizers and coatings during manufacturing to mitigate these effects. Regular maintenance, such as applying additional UV protectants, can further enhance their durability, especially in sunny climates.

-

Installation Techniques: Proper installation is essential for maximizing the durability of hollow polycarbonate sheets. This includes using compatible sealants, ensuring adequate framing and support structures, and following manufacturer guidelines for thermal expansion and contraction. Improper installation can lead to stress concentrations, water leakage, and mechanical failure over time.

-

Environmental Factors: The specific environmental conditions in which hollow polycarbonate sheets are installed can significantly impact their durability. For instance, coastal areas with high salt content in the air, or industrial environments with chemical pollutants, may accelerate degradation. Understanding these environmental factors allows for appropriate material selection and maintenance practices to mitigate potential risks.

-

Maintenance: Regular maintenance is key to prolonging the lifespan of hollow polycarbonate sheets. This includes cleaning to remove dirt, debris, and organic growth that can promote moisture retention and mold growth. Inspecting for cracks, scratches, or other signs of damage allows for timely repairs or replacements before issues escalate.

If you are interested in our products or have any further questions, please contact us at: simon@chiancess.com

.webp)