July 2, 2024

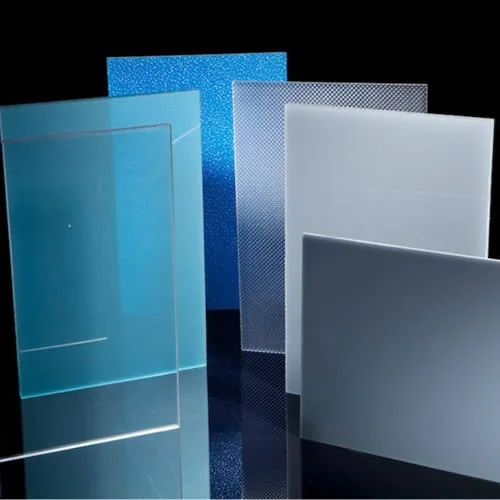

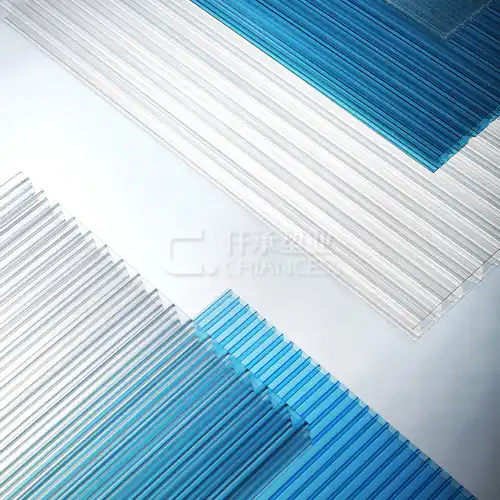

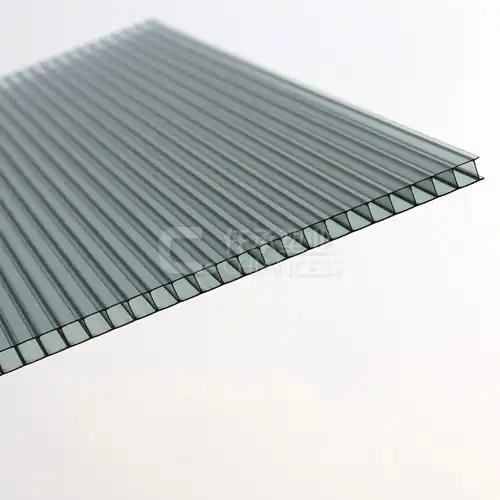

Polycarbonate is an incredibly versatile material, widely utilized across various applications due to its outstanding strength, remarkable impact resistance, and excellent optical clarity. Especially, strong polycarbonate sheets are leaned toward in various requesting conditions because of their excellent vigor and enduring strength. In this article, we will completely examine the essential strength of clear solid polycarbonate sheet, dive into their enormous number of usages, and check out at the key factors that influence their presentation and strength.

Additionally, we will discuss other important aspects that contribute to the widespread use and popularity of solid polycarbonate sheets in different industries, highlighting their multifaceted utility and benefits.

What Makes Solid Polycarbonate Sheet Strong?

The exceptional strength of 3mm solid polycarbonate clear sheet has earned them a reputation. They are roughly multiple times more grounded than glass and multiple times more grounded than acrylic. This incredible strength is a direct result of the sub-nuclear development of polycarbonate, which is a thermoplastic polymer made from carbonate bundles associated together by turning carbon particles.

Molecular Structure and Strength

The atomic design of polycarbonate contributes fundamentally to its solidarity. Polycarbonate molecules have high tensile strength because they are long chains with carbonate groups in their backbone. Polycarbonate is suitable for applications where durability and safety are of the utmost importance due to its ability to absorb impact without breaking because of its structure.

Impact Resistance

One of the key attributes of solid polycarbonate sheets is their impact resistance. They can withstand high impacts, making them virtually unbreakable. This property makes solid polycarbonate sheets ideal for applications requiring protection against vandalism, accidental breakage, or extreme weather conditions.

Testing and Standards

The strength of solid polycarbonate sheet clear is often evaluated through standardized testing methods. Tests such as the falling dart impact test and the ball drop test measure the ability of the material to withstand impact forces without fracturing. Polycarbonate sheets that meet or exceed these standards are considered suitable for high-stress applications.

Applications of Solid Polycarbonate Sheets

Solid clear solid polycarbonate sheet find applications across various industries where strength and durability are critical. Here are some common uses:

Construction and Architecture

They are an amazing choice for these undertakings because of their extraordinary solidness and strength. In contrast to conventional glass, polycarbonate sheets can endure huge effects from regular components like hail, falling branches, or other flotsam and jetsam. This versatility to affect improves security as well as decreases the gamble of breakage and injury. In addition, their lightweight nature works with more straightforward taking care of and establishment, while as yet giving great optical lucidity and UV opposition. These properties on the whole make strong polycarbonate sheets a better and more secure option than glass, guaranteeing durable execution and assurance in both private and business development projects.

Security and Vandalism Protection

Solid polycarbonate sheets are widely chosen for security glazing in a variety of critical facilities such as banks, detention centers, and public buildings due to their outstanding impact resistance. This feature ensures robust protection against forced entry attempts, vandalism, and in certain scenarios, even ballistic impacts. By virtue of their durability and strength, these sheets contribute significantly to enhancing the security infrastructure of sensitive environments. Their ability to withstand severe impacts without compromising structural integrity makes them an ideal choice for applications where safety and security are paramount concerns. Furthermore, solid polycarbonate sheets offer flexibility in design and installation, allowing for tailored solutions that meet specific security requirements. They are also known for their optical clarity and resistance to UV radiation, further enhancing their suitability for long-term use in security glazing applications. Ultimately, solid polycarbonate sheets stand out as a reliable and effective safeguarding solution in diverse settings requiring heightened security measures.

Automotive and Transportation

Solid polycarbonate sheets play a crucial role in the automotive industry, where they are utilized for various applications such as vehicle windows, sunroofs, and headlight covers. Their exceptional impact resistance is particularly valued for enhancing passenger safety by providing robust protection against road debris and other hazards. These sheets are engineered to withstand significant impacts without shattering, which is essential for maintaining the structural integrity of vehicle components and ensuring occupant safety. Moreover, solid polycarbonate sheets offer additional benefits such as lightweight construction and flexibility in design, allowing for innovative automotive designs that prioritize both safety and aesthetic appeal. Their resistance to weathering and UV radiation further extends their lifespan and performance, making them a preferred choice for manufacturers seeking durable and reliable materials for automotive glazing. Overall, solid polycarbonate sheets continue to uphold stringent safety standards in the automotive sector while supporting advancements in vehicle design and functionality.

Industrial Applications

Solid polycarbonate sheets are indispensable in industrial settings, serving multiple purposes such as machine guards, safety barriers, and protective shields. Their primary appeal lies in their ability to offer a clear view of operations while prioritizing employee safety in hazardous environments. These sheets are engineered to withstand impacts and resist shattering, thereby effectively safeguarding workers against potential risks posed by machinery and industrial processes. Beyond their durability, solid polycarbonate sheets are valued for their transparency and optical clarity, which ensure visibility without compromising safety measures. Their versatility allows for customization to fit specific industrial needs, including the integration of features such as UV protection and chemical resistance, which further enhances their utility in demanding industrial applications. By providing reliable protection and clear visibility, solid polycarbonate sheets contribute significantly to creating safer work environments and reducing workplace accidents, thus supporting productivity and operational efficiency in various industrial sectors.

Factors Influencing the Strength of Solid Polycarbonate Sheets

Several factors influence the strength and performance of clear solid polycarbonate sheet:

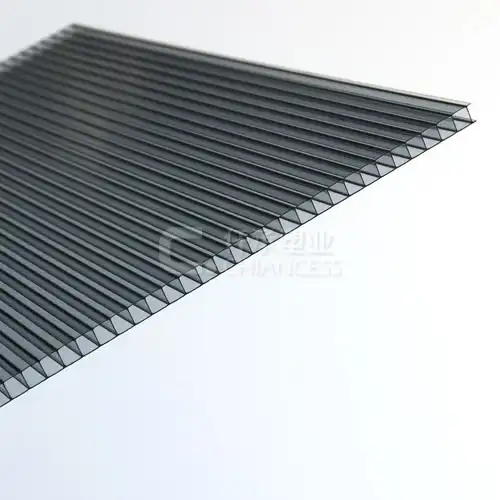

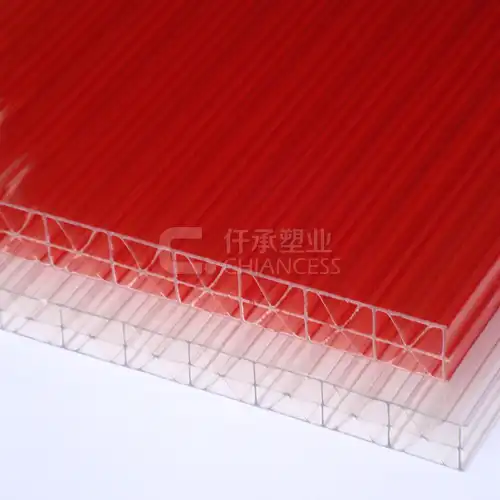

Thickness

The thickness of the polycarbonate sheet affects its strength. Thicker sheets generally offer higher impact resistance and are suitable for applications requiring greater durability.

UV Protection

Exposure to ultraviolet (UV) radiation can weaken polycarbonate over time. Therefore, solid polycarbonate sheets are often coated with UV-resistant materials to enhance their durability and maintain their strength in outdoor applications.

Installation and Maintenance

Proper installation and maintenance practices can impact the longevity and performance of solid polycarbonate sheets. Following manufacturer guidelines ensures that the sheets retain their strength and structural integrity.

Conclusion

3mm clear solid polycarbonate sheets are valued for their exceptional strength, impact resistance, and durability. Their sub-atomic design and extraordinary properties make them reasonable for a great many applications across different enterprises. Whether used in construction, security, automotive, or industrial settings, solid polycarbonate sheets provide a reliable and safe solution where strength is paramount.

For more information about solid polycarbonate sheets and their applications, please contact us at simon@chiancess.com.

References

American Plastics Council. (2020). Polycarbonate (PC) Plastic: Properties, Uses, & Structure. Retrieved from https://www.americanplasticscouncil.org.

Kuo, M. (2021). Polycarbonate: A Versatile, Strong Plastic. Retrieved from https://www.thoughtco.com.

Saeed, S. M., & Abd-El-Barr, M. M. (2020). Polycarbonate Sheets: A Comparative Review. Journal of Polymers and the Environment, 28(3), 685-699.

Ligon, S. C., & Liska, R. (2021). Polycarbonate and Poly(methyl methacrylate) (PMMA) Photopolymerizable Materials for Additive Manufacturing. ACS Applied Polymer Materials, 3(4), 1257-1269.

Foy, M. (2020). The Benefits of Using Polycarbonate. Retrieved from https://www.architectureanddesign.com.au.

Jain, S. K. (2021). Polycarbonate Sheets: Properties and Applications. Journal of Thermoplastic Composite Materials, 34(12), 1673-1694.

Schild, H., & Gindorf, H. (2021). Influence of UV Radiation on the Properties of Polycarbonate Sheets. Polymer Degradation and Stability, 183, 109444.

Krämer, M., & Schlosser, R. (2020). Impact Resistance of Polycarbonate Sheets: Experimental Investigation and Numerical Simulation. Materials Science and Engineering: A, 789, 139595.

ASTM International. (2021). Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimens by Means of a Striker Impacted by a Falling Weight (D 5628 - 20). Retrieved from https://www.astm.org.

.webp)