July 26, 2024

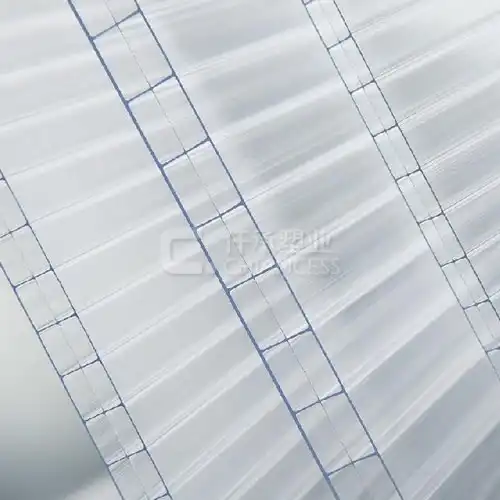

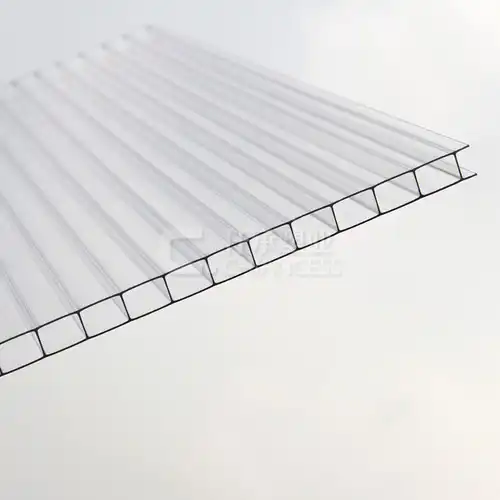

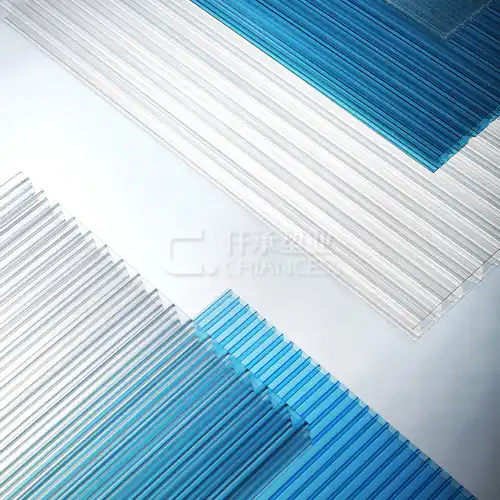

Twin wall polycarbonate sheets are widely used in construction and DIY projects for applications such as greenhouse glazing, roofing, and partitions. Joining these sheets together effectively requires proper techniques to ensure structural integrity and weather resistance. In this blog post, we will explore how to join polycarbonate twin wall sheets, covering the methods and tools needed for a successful installation.

What Tools and Materials Are Needed to Join Twin Wall Polycarbonate Sheets?

Joining twin wall polycarbonate sheets requires specific tools and materials to achieve a secure and weather-tight connection.

Here is a detailed list of essential items you will need for the task:

- Drill: A drill is necessary for creating holes in the polycarbonate sheets and the supporting structure. Choose a drill with a variable speed setting to avoid over-drilling and damaging the material.

- Circular Saw or Jigsaw: For cutting the sheets to size, you can use either a circular saw or a jigsaw. A circular saw is suitable for straight cuts, while a jigsaw is more versatile and can handle curved or intricate cuts.

- Measuring Tape and Marker: A measuring tape and marker are essential for measuring and marking cut lines and hole positions accurately. Ensure the markings are clear and visible for precise cutting and assembly.

- Screwdriver or Impact Driver: A screwdriver or impact driver is required for driving screws into the sheets and supporting structure. Choose a screwdriver with a magnetic tip to hold the screws securely while driving them in.

- Polycarbonate-Compatible Screws and Washers: Specifically designed for use with polycarbonate, these screws and washers help prevent cracking and ensure a secure attachment. They typically have a wider head and larger diameter than standard screws to distribute the load evenly.

- Polycarbonate-Compatible Sealant or Tape: To seal the joints between the polycarbonate sheets and prevent water infiltration, a polycarbonate-compatible sealant or tape is necessary. These sealants and tapes are specifically formulated to adhere to polycarbonate and provide a watertight seal.

How To Overlap Twin Wall Polycarbonate Sheets?

Step 1: Measure and Cut the Sheets

Measure the length of the area where the sheets will overlap and mark the sheets accordingly.

Use a circular saw or jigsaw to cut the sheets to the desired length.

Step 2: Install the Lower Sheet

Start with the lower sheet by aligning it with the supporting structure (e.g., rafters or studs).

Pre-drill holes through the sheet at regular intervals along the edges, ensuring the holes are slightly larger than the screw diameter to allow for expansion and contraction.

Attach the sheet to the structure using polycarbonate-compatible screws and washers, placing the screws in the middle of the pre-drilled holes to allow for movement.

Step 3: Install the Upper Sheet

Position the upper sheet over the lower sheet with a sufficient overlap (typically 4 inches or more).

Pre-drill holes in the upper sheet at the same intervals and size as the lower sheet.

Secure the upper sheet to the structure using screws and washers, ensuring they align with the lower sheet’s screws.

Step 4: Seal the Overlap

Apply a polycarbonate-compatible sealant or tape over the overlap between the two sheets to create a weather-tight seal.

Smooth the sealant or tape to ensure it adheres properly and prevents water infiltration.

How To Join Twin Wall Polycarbonate Sheets End-to-End?

Step 1: Measure and Cut the Sheets

Measure the width of the area where the sheets will join and mark the sheets accordingly.

Use a circular saw or jigsaw to cut the sheets to the desired width.

Step 2: Create a Support Structure

Ensure there is a supporting structure beneath the joint, such as a rafter or beam, to provide stability and prevent sagging.

Step 3: Install the Sheets

Place the first sheet against the support structure, ensuring it is level and aligned.

Pre-drill holes along the edge of the sheet at regular intervals, ensuring the holes are slightly larger than the screw diameter.

Step 4: Attach the Second Sheet

Position the second sheet next to the first, ensuring there is a small gap for expansion (approximately 1/8 inch).

Pre-drill holes in the second sheet at the same intervals and size as the first sheet.

Secure both sheets to the support structure using polycarbonate-compatible screws and washers.

Step 5: Seal the Joint

Apply a polycarbonate-compatible sealant or tape along the joint between the two sheets to prevent water infiltration.

Smooth the sealant or tape to ensure a secure seal.

4.Tips for Joining Twin Wall Polycarbonate Sheets

4.1.Use Proper Fasteners: Use polycarbonate-compatible screws and washers to prevent cracking and ensure a secure attachment.

4.2.Allow for Expansion and Contraction: Always leave a small gap between sheets and at the ends to allow for thermal expansion and contraction.

4.3.Seal Joints Properly: Apply a polycarbonate-compatible sealant or tape over the joints to create a weather-tight seal and prevent leaks.

Conclusion

In conclusion, Remember to use polycarbonate-compatible materials, such as screws and sealants, to prevent damage to the sheets and ensure a watertight seal. Additionally, consider factors such as sheet thickness, spacing, and the environmental conditions when selecting the appropriate joining method.

For more information about double wall polycarbonate sheets or assistance with your project, please do not hesitate to contact us at simon@chiancess.com. Our team of experts is always ready to provide guidance and support to help you make informed decisions and achieve successful outcomes with your polycarbonate projects.

References:

Professional Plastics. (2021). Polycarbonate - Multiwall Sheets. Professional Plastics.

Industrial Polycarbonate Sheets. (2021). Installation Guidelines for Multiwall Polycarbonate Sheet. Industrial Polycarbonate Sheets.

The British Plastics Federation. (2019). Polycarbonate - A Sustainable Material for the Future. The British Plastics Federation.

Plastics Industry Association. (2020). Plastic Materials and Resins. Plastics Industry Association.

Society of Plastics Engineers. (2020). Polymer Science and Engineering. Society of Plastics Engineers.

ASTM International. (2018). Standard Test Methods for Plastics: Polycarbonate Roofing Sheets. ASTM International.

American Chemistry Council. (2019). Polycarbonate Safety Data Sheet. American Chemistry Council.

U.S. National Library of Medicine. (2020). Health and Safety Guide for Working with Polycarbonate. U.S. National Library of Medicine.

.webp)