July 5, 2024

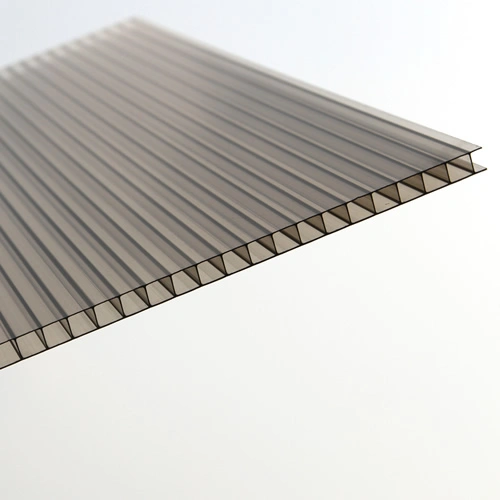

Hollow polycarbonate sheet manufacturers materials are widely chosen for door awnings due to their distinct attributes. Hollow polycarbonate offers exceptional durability and impact resistance, making it ideal for areas prone to harsh weather conditions or potential impacts. It also provides good light transmission, allowing natural light while blocking harmful UV rays. However, it can be more expensive and may scratch easier than other materials.

On the other hand, polycarbonate hollow sheet materials are lightweight and cost-effective, offering decent weather resistance and UV protection. They are easier to install and maintain but may not be as durable as polycarbonate and could potentially yellow over time with prolonged sun exposure. Choosing between these options often depends on factors like budget, climate, and desired longevity, ensuring the awning meets both aesthetic and practical requirements effectively.

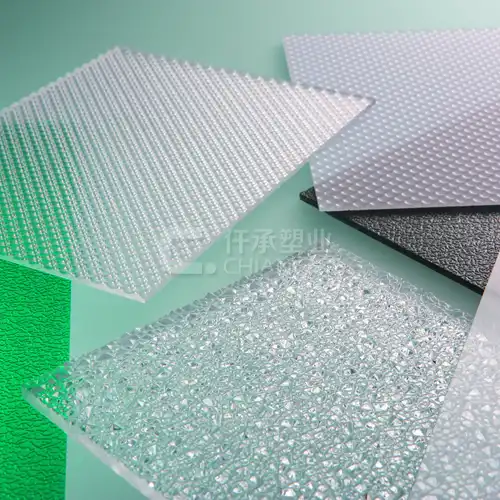

What Are Polycarbonate and Hollow Sheet Materials?

1.1. Polycarbonate Materials

Hollow polycarbonate stands out as a transparent thermoplastic renowned for its exceptional impact resistance, high transparency, and robust durability. Its versatility finds extensive use in door awnings and numerous other applications, offering reliable protection against harsh weather while allowing ample natural light transmission. This material's resilience makes it a preferred choice where strength and longevity are paramount, ensuring enduring performance in challenging outdoor environments.

1.2. Hollow Sheet Materials

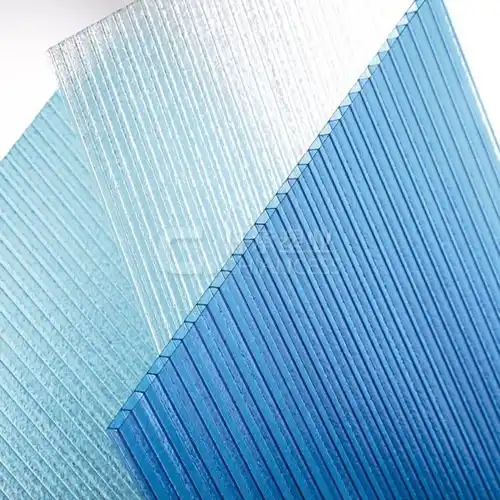

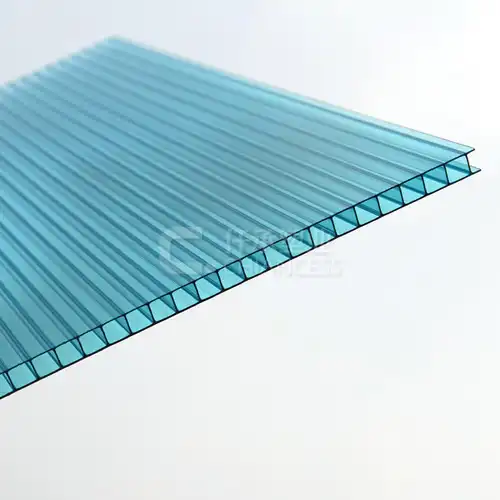

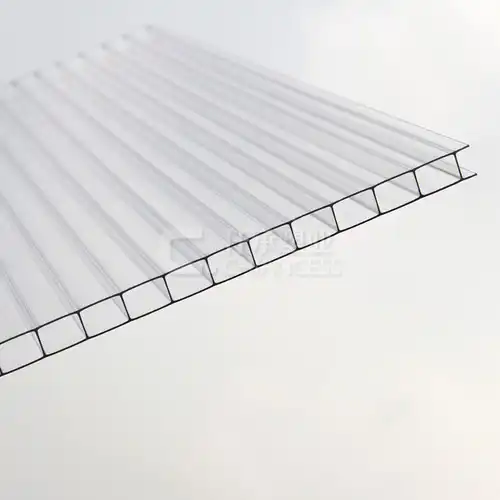

The hollow, ribbed structure of hollow sheet polycarbonate materials, which are typically made of polycarbonate or other plastics of a similar composition, distinguishes them from other sheet materials in that they offer both strength and lightness.

These sheets are widely used in entryway shades, actually safeguarding against daylight and climate components like downpour and snow. Their creative plan guarantees strength as well as works with simple establishment and support. This goes with them a famous decision for private and business applications where security from the components and stylish allure are principal.

Advantages of Polycarbonate for Door Awnings

2.1. Impact Resistance and Durability

Hollow polycarbonate is renowned for its exceptional impact resistance, which makes it an ideal material for regions that frequently experience hail or other forms of physical impacts. This robust characteristic ensures that polycarbonate can endure significant force without sustaining damage. Additionally, polycarbonate is extremely long-lasting and resistant to cracking or breaking under extreme weather conditions like intense heat, cold, and heavy rainfall. Its flexibility and life span pursue it a favored decision for different applications, including material, nurseries, and defensive boundaries, where both security and sturdiness are basic. This combination of strength and weather resistance ensures reliable performance over an extended period.

2.2. High Light Transmission

Polycarbonate is a flexible material that allows a high level of light to go through while at the same time offering viable UV security. This unique feature is especially useful for door awnings because it lets a lot of natural light illuminate the doorway area without putting people inside or the furniture there in danger from UV rays. Polycarbonate aids in the prevention of sun damage and the fading of interior materials by filtering out UV radiation. Moreover, the lucidity and light transmission properties of polycarbonate upgrade the tasteful allure of the space, making a brilliant and inviting entry. It is an excellent option for both residential and commercial awning applications due to its combination of transparency and protection.

2.3. Longevity and Low Maintenance

Polycarbonate door awnings are long-lasting and require minimal maintenance. They are resistant to yellowing and degradation from UV exposure, ensuring they maintain their clarity and appearance over time.

Advantages of Hollow Sheet for Door Awnings

3.1. Lightweight and Ease of Installation

polycarbonate hollow sheet materials, such as those made from polycarbonate or similar plastics, offer significant advantages due to their lightweight nature. Unlike solid polycarbonate sheets, which can be heavy and cumbersome to maneuver, hollow sheets are lighter and easier to handle during installation. This characteristic not only simplifies the installation process but also reduces the labor costs associated with handling and positioning the sheets into place. Contractors and DIY enthusiasts alike appreciate the reduced weight of hollow sheets, as it minimizes the physical strain and effort required to transport and install them on-site. Additionally, the faster installation times are made possible by hollow sheet materials' lighter weight. Homeowners and businesses can save time and money by working with contractors, who may be able to finish projects sooner. Hollow sheets remain robust and structurally sound despite their lighter weight, ensuring dependable performance upon installation. This blend of lightweight development and strength goes with empty sheet materials a favored decision for different applications, including entryway shades, material, and nursery covers.

3.2. Cost-Effectiveness

The fact that materials made of hollow sheet are typically less expensive than their solid polycarbonate counterparts makes them an appealing choice for a wide range of uses. These sheets offer a favorable balance between high performance and affordability, which makes them particularly appealing for budget-conscious projects. The reduced material usage in the manufacturing of hollow sheets contributes to their lower cost, without significantly compromising their strength or functionality.

In addition to being economical, hollow sheet materials still provide excellent thermal insulation and impact resistance, similar to solid sheets. This makes them suitable for various uses, such as roofing, greenhouses, and partitions, where both cost efficiency and material performance are critical considerations. Their lightweight nature further enhances their value proposition by reducing transportation costs and simplifying installation processes, ultimately saving on labor expenses.

Due to these benefits, hollow sheet materials have become a popular choice among builders, architects, and DIY enthusiasts who seek to maximize their budgets without sacrificing quality. This blend of affordability, ease of handling, and robust performance ensures that hollow sheet materials remain a go-to solution for numerous construction and renovation projects.

3.3. Thermal Insulation

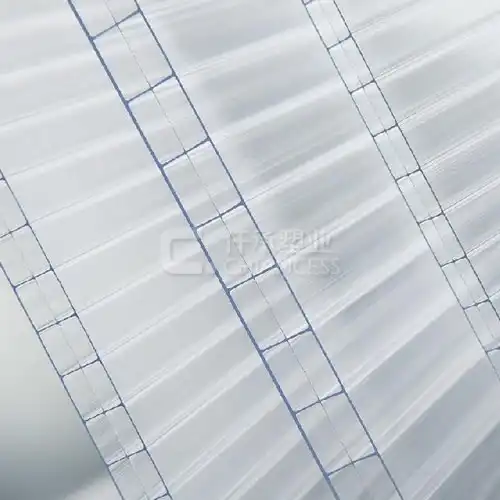

The hollow structure inherent in these sheets offers superior thermal insulation properties when compared to solid polycarbonate alternatives. This attribute is particularly beneficial in building applications as it aids in maintaining stable indoor temperatures, thereby reducing the need for excessive heating or cooling. By effectively trapping air within their chambers, hollow sheet polycarbonate materials create a barrier against heat transfer, enhancing the building's overall energy efficiency. This improved thermal insulation not only helps to regulate temperatures inside structures but also contributes to lowering energy consumption and operational costs over time. Buildings equipped with hollow sheet materials can benefit from reduced reliance on HVAC systems, resulting in decreased energy bills and a smaller carbon footprint.

Moreover, the lightweight nature of these sheets makes them easier to handle during installation, further streamlining the construction process and potentially reducing labor costs. Overall, the combination of enhanced thermal insulation capabilities and cost-effectiveness makes hollow sheet materials a preferred choice for architects, contractors, and homeowners alike. Whether used for roofing, skylights, or partitions, their ability to create a more comfortable indoor environment while promoting energy efficiency underscores their value in modern construction practices.

Disadvantages of Polycarbonate for Door Awnings

4.1. Weight

Solid polycarbonate sheets are significantly heavier than hollow sheet materials, a factor that can complicate the installation process. The increased weight of solid sheets often necessitates additional structural support to ensure they are securely and safely installed. This requirement can lead to higher material and labor costs, as more robust framing and additional manpower may be needed to handle the heavier sheets. In contrast, hollow sheet materials, being lighter, are easier to manage and install, reducing the need for extensive support structures and potentially lowering overall project expenses. This difference makes hollow sheets a more practical choice for many construction and renovation projects.

4.2. Initial Cost

Polycarbonate sheets, particularly the solid variants, tend to have a higher upfront cost compared to hollow sheet materials. This initial expense can be a significant consideration for budget-conscious projects or large-scale installations. The manufacturing process and material density contribute to the increased price of solid polycarbonate sheets. In contrast, hollow sheet materials, which use less raw material while still providing adequate strength and durability, offer a more cost-effective solution. This makes hollow sheets an attractive option for those looking to balance performance and budget, providing substantial savings without compromising on essential qualities like impact resistance and thermal insulation.

Disadvantages of Hollow Sheet for Door Awnings

5.1. Durability

In regions that experience high breezes or hail, strong polycarbonate sheets are frequently viewed as more solid than empty sheet materials. The structure's greater resistance to external forces makes it less likely to be damaged or deformed. Despite their reasonable strength and impact resistance, hollow sheets may not be as strong against harsh weather conditions.

5.2. Light Transmission

Hollow sheet materials typically exhibit lower light transmission capabilities compared to solid polycarbonate sheets. This characteristic can result in reduced natural light entering areas near doorways and other openings. The design of hollow sheets, with their chambers and structured composition, inherently diffuses and blocks some incoming light. While they still provide adequate illumination for many applications, including roofing and partitions, solid polycarbonate sheets generally offer higher light transmission percentages. This makes solid variants preferable in situations where maximizing natural light penetration is crucial, such as doorways and windows, to enhance visibility and create a brighter, more inviting indoor environment.

Conclusion

In conclusion, both polycarbonate and hollow sheet materials offer advantages and disadvantages for door awnings. Hollow polycarbonate is preferred for its superior impact resistance, high light transmission, and durability, making it suitable for areas requiring robust protection and longevity. On the other hand, hollow sheet materials are valued for their lightweight nature, ease of installation, and cost-effectiveness, making them a practical choice for less demanding applications.

When choosing between polycarbonate and hollow sheet materials for door awnings, consider factors such as the specific environmental conditions, budget, and aesthetic preferences. For more information or assistance in selecting the right material for your project, please contact us at simon@chiancess.com.

References:

Professional Plastics. (2021). Polycarbonate - Multiwall Sheets. Professional Plastics.

Industrial Polycarbonate Sheets. (2021). Installation Guidelines for Multiwall Polycarbonate Sheet. Industrial Polycarbonate Sheets.

The British Plastics Federation. (2019). Polycarbonate - A Sustainable Material for the Future. The British Plastics Federation.

Plastics Industry Association. (2020). Plastic Materials and Resins. Plastics Industry Association.

Society of Plastics Engineers. (2020). Polymer Science and Engineering. Society of Plastics Engineers.

ASTM International. (2018). Standard Test Methods for Plastics: Polycarbonate Roofing Sheets. ASTM International.

.webp)