May 28, 2025

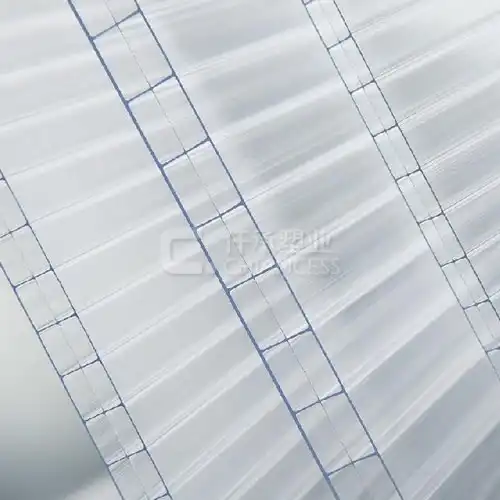

What is Polycarbonate Sheet

Polycarbonate Sheet, also known as PC Sunlight Panel, is a transparent or translucent sheet made of polycarbonate (PC for short) as the main raw material. Due to its excellent performance, it is widely used in construction, agriculture, industry and other fields, replacing traditional glass or acrylic materials.

Installation instructions:

1. Calculation method of practical installation radius The minimum radius allowed for bending of polycarbonate sheet of different thicknesses is different. For detailed minimum bending radius, please refer to the following instructions.

2. Before installation, the protective film should be lifted along the edge to leave space for the beading strip so that the beading polycarbonate sheet directly touches the panel. After the installation of the gusset plate is completed, the protective film should be completely torn off. Do not install the panel with the protective film and then cut the protective film along the edge of the beading strip, because it is easy to leave scratches on the panel and the panel will crack along the scratches. If the polycarbonate sheet is fixed with screws, the aperture should be more than 0.5 times the diameter of the screw to prevent deformation caused by cold and hot shrinkage and damage to the panel

3. The joints of the two panels need to reserve sufficient elastic space according to the change of local temperature difference. Under normal circumstances, the gap width is more than 50% of the screw diameter

4. Please use special sealant. Other types of sealants may corrode the panel, making it brittle and easy to crack. PVC seals will corrode the board. When installing the polycarbonate board, it is necessary to select sealant paste and rubber pads suitable for polycarbonate plastics. It is strictly forbidden to use PVC seals and gaskets. The board surface is taboo to contact alkaline substances and corrosive organic solvents, such as alkali, amine, ketone, aldehyde, ether, halogenated hydrocarbons, aromatic hydrocarbons, formaldehyde propanol, etc.

5. It is forbidden to drill screws directly on the board during construction. The screw holes should be drilled first, and then the screws should be screwed. If the board needs to bend, screws are forbidden to be screwed at the bending stress point.

6. The polycarbonate sheet can be bent, which means that it can be bent into a smooth arc, not into any shape. When cold bending, the bending direction must be perpendicular to the direction of the board ribs. The cold bending radius of the polycarbonate board must be greater than 175 times the thickness of the board, and the cold bending radius of the endurance board must be greater than 100 times the thickness of the board. Cold bending radius calculation formula: R=1/2h+m/8h (R=bending radius: h=arch height: m=span).

7. To allow for the expansion and displacement of the board during drilling and installation, the diameter of the drill hole should be greater than 50% of the screw diameter, and the distance from the screw hole to the edge of the board should be no less than 50mm. The screws should not be too tight. The screws should not be too dense. It is recommended to use one screw every 50cm or more (the thicker the board, the greater the screw distance required).

8. Be careful not to contact with corrosive chemical solvents to avoid damage to the board. Please use a neutral detergent or a non-corrosive detergent and water to scrub to avoid surface marks.

Note:

During installation: space for thermal expansion and contraction needs to be reserved, and the edges of the board need to be sealed (special rubber strips or glue) to prevent dust and moisture.

When cleaning: avoid scratching with hard objects, and wipe with a soft cloth and neutral detergent.

Avoid contact: strong alkali, organic solvents (such as acetone), which may corrode the surface.

.webp)