July 17, 2024

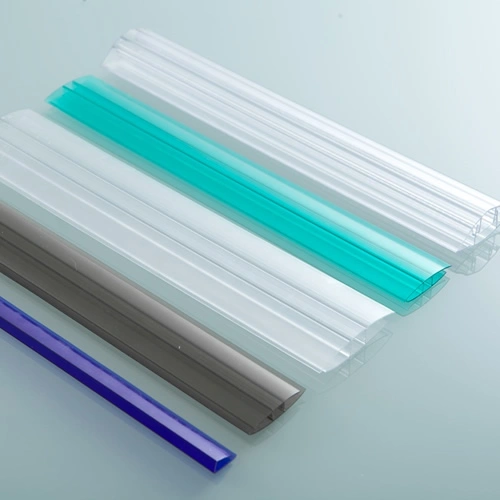

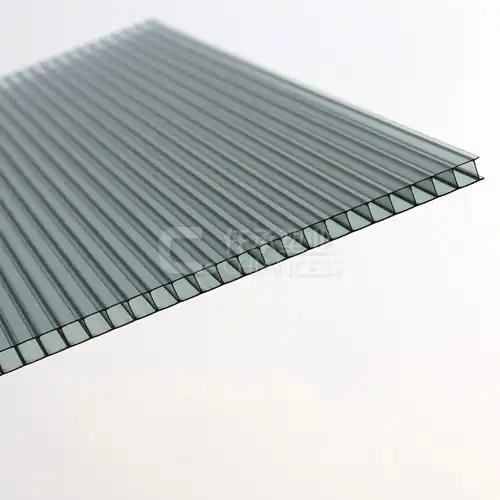

Due to their unique properties, polycarbonate profiles are versatile materials that are utilized in a wide range of industries. These profiles, which come in a variety of sizes and shapes, are well-known for being impact-resistant, transparent, and long-lasting. They play a crucial role in a variety of fields, including electronics, signage, construction, and automotive. This blog examines the numerous applications of polycarbonate , focusing on their advantages, specific applications, and the reasons why they are preferred in many industries.

Why Are Polycarbonate Profiles Popular in Construction?

Due to their exceptional properties that meet a variety of modern building project requirements, polycarbonate profiles have gained popularity in the construction industry. These profiles are durable and resistant to impacts, ensuring longevity and safety in a variety of settings. Because they are so light, they are easier to handle and put in, which saves money on labor and lightens the load on the structure. Additionally, polycarbonate offer excellent thermal insulation, which aids in energy efficiency by lowering the cost of heating and cooling. Additionally, they permit a variety of shapes and configurations to satisfy particular architectural requirements thanks to their design adaptability. Polycarbonate profiles are a popular choice for contemporary construction projects because they can be used for skylights, façades, roofing, or both.

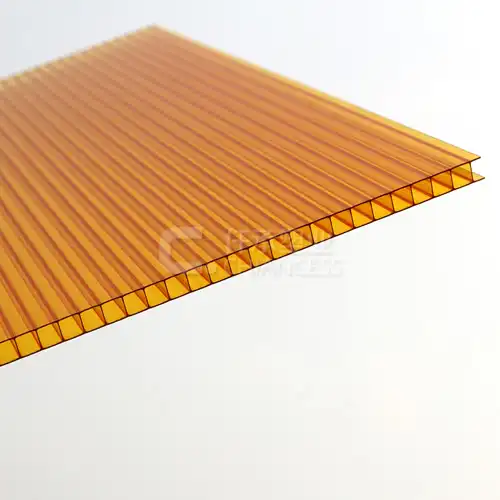

Durability and Strength

Due to their strength and durability, materials like polycarbonate are highly sought after in numerous applications. Polycarbonate excels in both of these areas due to its exceptional resistance to impacts and adverse weather conditions. Due to its capacity to withstand high levels of force without breaking or shattering, it is ideal for construction, automotive components, and protective equipment applications. Due to their durability, products have longer lifespans and cost less to maintain. Additionally, polycarbonate's inherent strength and light weight make installation and handling simpler than those of conventional materials like glass or metal. Polycarbonate is the material of choice when robust performance and structural integrity are essential considerations.

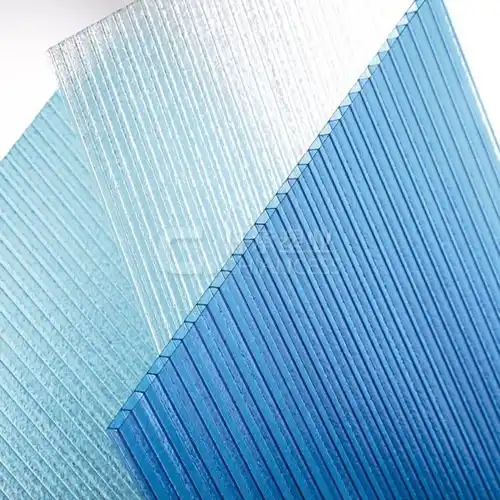

Light Transmission

Polycarbonate profiles offer excellent light transmission, which is one of their primary advantages. They effectively block harmful UV rays while allowing up to 90% of natural light to pass through, making them ideal for skylights, conservatories, and greenhouses. In these applications, getting as much natural light as possible is crucial for plant growth and energy savings. Polycarbonate are an excellent choice for a variety of construction applications due to their ability to let in natural light without compromising safety or durability.

Insulation Properties

Additionally, polycarbonate outperform conventional glass in terms of thermal insulation. They reduce the need for additional heating or cooling systems by helping to maintain a consistent indoor temperature. As a result of this energy efficiency, you'll pay less for utilities and leave a smaller carbon footprint. Polycarbonate are a popular choice for facades, partition walls, and glazing in commercial buildings because they are both attractive and useful.

Ease of Installation and Customization

Another factor contributing to the popularity of polycarbonate in construction is their ease of installation. Due to their lightweight nature, the handling and installation of these materials is facilitated, thereby reducing the stress placed on the underlying structure. Furthermore, the simplicity of cutting and shaping polycarbonate allows for greater creativity and adaptability in architectural projects.

How Are Polycarbonate Profiles Utilized in the Automotive Industry?

Polycarbonate profiles are advantageous to the automotive industry due to their durability, lightweight nature, and design adaptability.

Weight Reduction

The significant weight reduction they provide is one of their primary advantages in the automotive industry. Because polycarbonate is significantly lighter than glass, the vehicle's overall weight can be reduced. Better fuel economy and lower emissions as a result of this weight reduction contribute to a more sustainable automotive industry. Polycarbonate profiles are frequently used in parts like windows, sunroofs, and headlamp lenses to get these benefits.

Safety and Impact Resistance

When choosing a material, safety and impact resistance are of the utmost importance, and polycarbonate excels in both of these areas. Polycarbonate is extremely safe for applications requiring protective barriers, safety glasses, and automotive components due to its reputation for its ability to withstand high impacts without shattering. By reducing the likelihood of injury caused by breakage or fragmentation, this resilience improves user safety. Its resistance to impact also extends the product's lifespan, lowering the cost of replacement over time. Additionally, polycarbonate's strength-to-weight ratio is advantageous in applications requiring lightweight materials with robust protection. Polycarbonate is a dependable option for demanding environments due to its superior safety profile, whether used in construction, manufacturing, or consumer goods.

Design Flexibility

Polycarbonate profiles enable automotive manufacturers to create novel designs and intricate shapes that would be difficult to achieve with conventional materials due to their unparalleled design adaptability. This flexibility makes it easier to create vehicle parts that look good and are aerodynamic. Covers for headlamps and taillights, for instance, are created using polycarbonate . For these covers to function and look good, they must be made of clear, long-lasting materials with intricate shapes.

Thermal Management

The management of heat is of paramount importance to the performance and longevity of various components in automotive applications. Polycarbonate are optimal for components that are susceptible to elevated temperatures due to their exemplary thermal resistance. Such components are utilised in locations such as the engine bay, where durability and resistance to heat are of paramount importance. Furthermore, the overall driving experience is enhanced by their insulating qualities, which assist in maintaining a comfortable interior temperature.

Noise Reduction

By reducing noise, polycarbonate profiles contribute significantly to the improvement of vehicle comfort. They effectively dampen vibrations and reduce road noise thanks to their excellent insulation properties, making driving more pleasant and quieter. Due to the absence of traditional internal combustion engine sounds, the development of electric vehicles necessitates this acoustic insulation, making noise reduction a top priority. Polycarbonate profiles contribute to the creation of a tranquil cabin environment by minimizing external noise intrusion, thereby enhancing passenger comfort. In addition to enhancing the vehicle's acoustic performance, this capability is in line with the sector's emphasis on sustainability and customer satisfaction. As a result, modern automobile designs incorporate polycarbonate profiles as essential components that enhance driving pleasure and functionality at the same time.

What Makes Polycarbonate Profiles Ideal for Electronics and Signage?

Due to their exceptional properties, polycarbonate profiles are excellent for signage and electronics. They are extremely resistant to impact, which is essential for safeguarding delicate electronic components from accidental damage. Their durability makes sure they last in harsh environments and keep their functionality for a long time. Because of its optical clarity and transparency, polycarbonate is ideal for use in signage applications where clear visibility and readability are crucial. Polycarbonate profiles can also be easily molded into a variety of shapes and sizes, meeting a wide range of design needs for electronics housing and signage structures. The material's resistance to weathering and ultraviolet light further enhances its suitability for outdoor applications, ensuring signage displays' color retention and durability. Polycarbonate , which effectively satisfy both aesthetic and functional requirements, are the preferred choice in the electronics and signage industries due to their combination of durability, optical clarity, customization capabilities, and weather resistance.

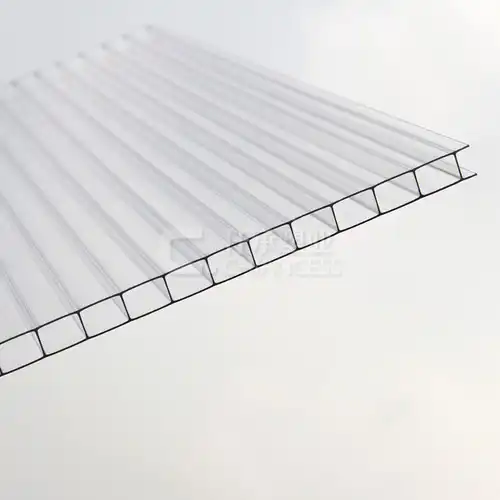

Transparency and Clarity

Profiles made of polycarbonate have clarity comparable to that of glass and are highly transparent. Applications like electronic displays, screens, and protective covers require clear visibility, so this property is crucial. This transparency ensures that signs in the signage industry are easily readable and visually appealing even from a distance. Polycarbonate profiles are a dependable option for both indoor and outdoor applications due to their ability to maintain clarity over time without yellowing or deteriorating.

Durability and Impact Resistance

Polycarbonate profiles' durability and resistance to impact are crucial in the electronics industry, where delicate components must be safeguarded. These profiles offer robust protection for devices like smartphones, tablets, and industrial equipment because they are able to withstand significant impacts without cracking or breaking. This durability ensures that even in harsh environments, signs will remain legible and intact.

Thermal Stability and Fire Resistance

Thermal stability is a crucial aspect in electronic applications. Polycarbonate are suitable for use in heat-generating devices due to their excellent thermal resistance. They ensure the dependability and long-term durability of electronic components by ensuring that they can withstand high temperatures without becoming distorted. Polycarbonate are also naturally flame retardant, providing an additional layer of protection for electronic devices and public signage.

Lightweight and Easy to Fabricate

Polycarbonate are advantageous in the electronics and signage industries due to their light weight. Enhancing portability and user convenience in electronics require devices to be lighter. This is made possible with the aid of polycarbonate without sacrificing strength or durability. The lightweight nature of signage makes it easier to mount signs in a variety of locations because it makes installation simpler and lighter on supporting structures.

UV Resistance

UV-resistant coatings are frequently applied to polycarbonate to prevent degradation from prolonged sunlight exposure. This resistance to UV light is especially useful for outdoor signage because it ensures that signs will remain vivid and legible over time. UV resistance helps protect displays and covers in electronic applications from yellowing and damage, preserving the devices' aesthetic and functional qualities.

In conclusion, polycarbonate are valuable in a variety of industries due to the unique combination of their properties. Signage, the automotive industry, electronics, and construction all benefit from these profiles' unrivaled durability, clarity, and adaptability. If you are interested in our polycarbonate , please get in touch with us at: simon@chiancess.com.

References

- Polycarbonate - Wikipedia

- The Benefits of Using Polycarbonate Roofing Sheets - Homebuilding & Renovating

- Polycarbonate vs Acrylic: What are the Differences? - Acme Plastics

- Polycarbonate Profiles in the Construction Industry - A&C Plastics

- Advantages of Polycarbonate in Automotive Applications - Covestro

- Polycarbonate Sheets for Greenhouses - Growers Supply

- Thermal Insulation Properties of Polycarbonate - Palram

- Polycarbonate Applications in Electronics - Professional Plastics

- The Use of Polycarbonate in Signage - Sign Industry News

- UV Resistance and Polycarbonate - Interstate Plastics

.webp)