July 29, 2024

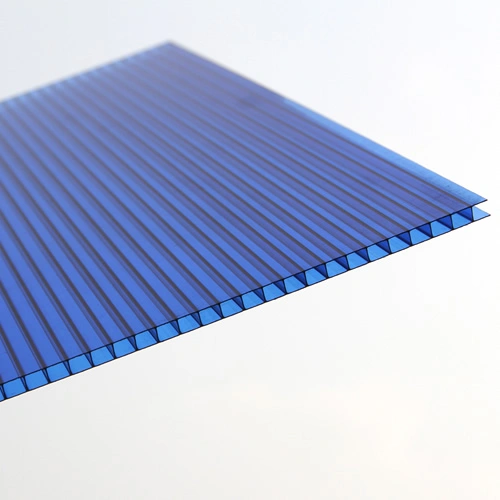

Hollow polycarbonate sheets are used in a wide range of applications due to their adaptability and exceptional properties. For two or three persuading reasons, these sheets are legitimately liked to standard materials like glass or acrylic.

In the field of development, empty polycarbonate sheets are highly regarded for their combination of strength and lightness. They are more secure and more dependable in harsh conditions than glass because they have a substantially higher protection from influence. Due to its resistance to hail, wind, and UV rays, polycarbonate will never turn yellow or deteriorate due to the weather.

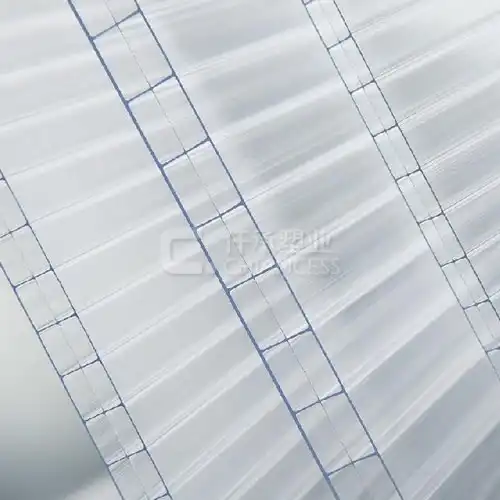

Polycarbonate sheets are a popular choice for construction due to their warmth-protective properties. They effectively regulate internal temperatures by maximizing heat gain in hot weather and minimizing heat loss in cold weather. This energy efficiency not only makes the home feel more comfortable, but it also saves money over time on heating and cooling costs.

Polycarbonate can be easily shaped, twisted, and sliced to meet specific plan requirements due to its adaptability. Many imaginative possibilities in engineering and configuration can now be realized thanks to this adaptability, including extraordinary designs and components that might be out of reach or prohibitively expensive with other materials.

In addition to construction, hollow polycarbonate can be used for a wide range of industrial and home improvement projects. Due to its ease of use and installation, it is suitable for a variety of DIY projects, including defensive barriers, signage, and nursery fenced-in areas. Due to its transparency and resistance to impact, polycarbonate is ideal for machine guards, protective covers, and safety shields in industrial settings where visibility and durability are crucial.

Due to their strength, energy efficiency, adaptability, and variety of business applications, empty polycarbonate sheets are becoming increasingly popular. By offering an exceptional mix of unrivaled execution and plan flexibility unparalleled by traditional materials, these sheets keep on exhibiting their worth. As a result, they are ideal for use in modern, development, and DIY projects.

How durable is hollow polycarbonate?

The primary reason for their popularity is the superior durability of hollow polycarbonate sheets, which outperform conventional materials like glass in a number of significant ways. One of their most remarkable attributes is that they are essentially strong under typical conditions because of their high effect opposition. Polycarbonate is a phenomenal choice for conditions where wellbeing and toughness are critical.

Polycarbonate's capacity to endure actual power without breaking guarantees that plants stay safeguarded and activities proceed with continuous in nurseries, where security from hailstorms and other effect occasions is fundamental. Polycarbonate sheets are durable enough to be used in public areas that are prone to vandalism because they keep their structural integrity even when deliberately damaged.

Additionally, polycarbonate is better suited for outdoor use due to its resistance to harsh weather conditions. It can withstand extreme temperatures without deteriorating or becoming brittle, which makes it particularly useful in locations with distinct climate patterns. UV resistance is another notable feature that preserves optical clarity and aesthetic appeal while preventing yellowing or degrading over time.

In addition to its physical durability, polycarbonate's light weight makes it easier to handle and install than heavier alternatives like glass. This property increases application flexibility in design and construction in addition to reducing installation costs and time.

In conclusion, due to their exceptional durability, hollow polycarbonate sheets are preferred in settings where robustness, safety, and long-term performance are crucial. Polycarbonate's capacity to endure influences, brutal climate, and UV radiation guarantees unwavering quality and life span unparalleled by different materials, whether it is utilized in nurseries, design tasks, or public framework.

What are the advantages of using hollow polycarbonate in construction?

In the construction industry, hollow polycarbonate sheets offer several advantages. Firstly, their lightweight nature makes handling and installation easier compared to traditional materials. This weight advantage also translates into reduced structural support requirements, leading to cost savings and faster construction times. Moreover, the thermal insulation properties of polycarbonate contribute to energy efficiency in buildings, helping to maintain stable indoor temperatures and reduce heating or cooling costs. Architects and designers appreciate the design flexibility that polycarbonate offers, allowing for curved installations and creative architectural features while maintaining structural integrity.

How does hollow polycarbonate compare to other materials in terms of versatility?

Versatility is another key benefit of hollow polycarbonate sheets. They are available in various colors, thicknesses, and sizes, catering to diverse application needs. Whether used as roofing panels for skylights, partitions in office spaces, or safety barriers in sports arenas, polycarbonate sheets offer flexibility without compromising on performance. Their ability to be easily cut, shaped, and molded to fit specific project requirements enhances their appeal across different industries. Furthermore, advancements in manufacturing techniques have resulted in enhanced UV protection coatings and anti-condensation treatments, further expanding their usability in outdoor and indoor applications.

If you are interested in our products, you can contact us at: simon@chiancess.com

.webp)