June 4, 2025

Polycarbonate Sheets are mainly used in greenhouses, industrial, civil and municipal engineering lighting projects. Its main purpose is to resist sunlight and aging. Since the Polycarbonate Sheets are hollow, they are not subject to force. At present, Polycarbonate Sheets are very popular in rural areas. Since the Polycarbonate Sheets are relatively large, it is inconvenient to load and ship them. Most of them are loaded in the form of rolled panels. As manufacturers also consider the actual delivery problems, they have always defaulted to the dealers' delivery method. In fact, this method is very unfavorable for hollow panels with a small bending radius. At present, 90% of the folding and bursting of the panels in the market basically occur during the rolling process.

There have been manufacturers who have issued reminders to dealers that the folding and bursting caused by too small rolling of the panels are not responsible. However, if this is the case, it will bring inconvenience to the dealers and affect sales. In fact, for the detailed instructions on the transportation, installation, maintenance, etc. of the panels, we, Chiancess Plastic Industry, have printed these on the PE protective film that protects the Polycarbonate Sheets. In fact, for high-end panels, it is more necessary to comply with product technical parameters because of its thick wall and UV layer.

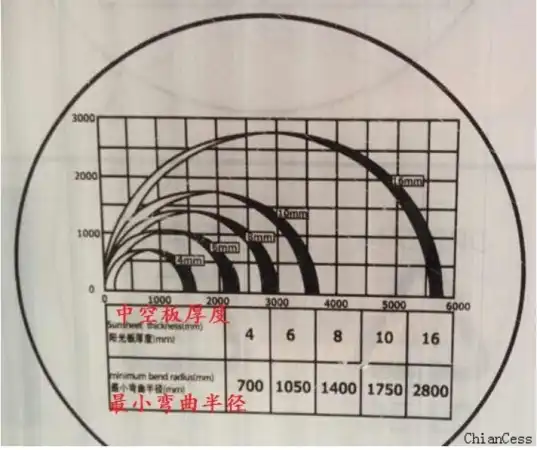

Analysis of the above picture: The width of the small truck compartment is about 1.3 meters. The above picture shows two rolls placed side by side, which means that the diameter of each roll is about 65CM, which is the size of the outermost circle. Then, minus the outer circles of 10CM, the diameter of the innermost circle has to be minus 2 10CM, which is equivalent to a diameter of less than 45, and the radius is about 225mm [far from the manufacturer's minimum parameter of 700mm]. It is a miracle if it does not burst or fold. (If it is a low-end board with the same thick wall, it should have burst and folded long ago) For the UV co-extruded Chiancess sunshine board, even if the board does not burst or fold, it will actually cause invisible damage to the board. Because the wall of the Polycarbonate Sheets is thicker than that of ordinary low-end boards, when the roll is compared with the cheap low-end hollow board of ordinary thickness, it is easier to burst. In other words, the sunshine board is more difficult to bend. Too small a bend will not only cause invisible damage to the board, but also affect the use effect of the UV surface.

The above figure shows the minimum bending radius corresponding to each thickness of the solar panel

Of course, buyers or dealers can also use this method to transport Polycarbonate Sheets.

.webp)