August 7, 2024

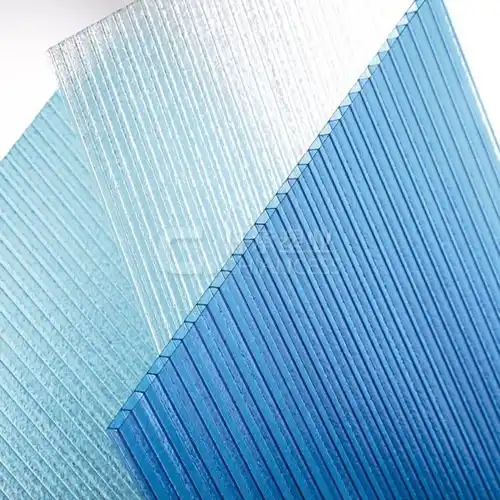

Polycarbonate honeycomb sheets are innovative substances that have become increasingly popular across an assortment of sectors owing to their outstanding features and unusual construction.

What is a Polycarbonate Honeycomb Sheet?

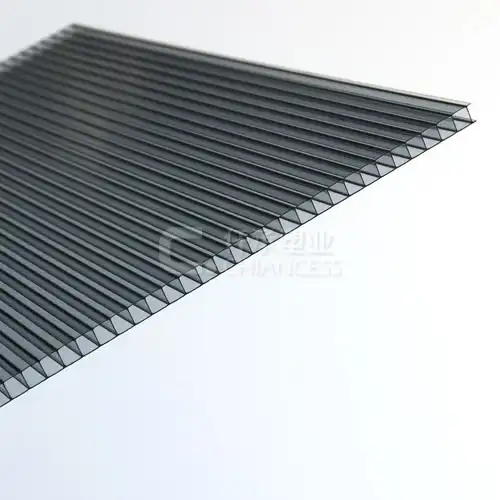

Honeycomb polycarbonate sheets are advanced composite materials characterized by their unique honeycomb structure, which consists of hexagonal cells.

Usually built from polycarbonate, which a resistant to impacts and a lightweight plastic material renowned for its ocular clarity and longevity, these sheets are strong yet lightweight.

The honeycomb structure provides several key advantages:

Strength-to-Weight Ratio: The honeycomb structure creates an excellent strength-to-weight ratio. This means that polycarbonate honeycomb sheets are lightweight yet highly resistant to bending and compression. They can withstand significant loads without deforming or breaking.

Impact Resistance: Polycarbonate is renowned for its impact resistance, and the honeycomb structure further enhances this property. The hexagonal cells act as shock absorbers, dissipating impact energy and preventing damage to the sheet.

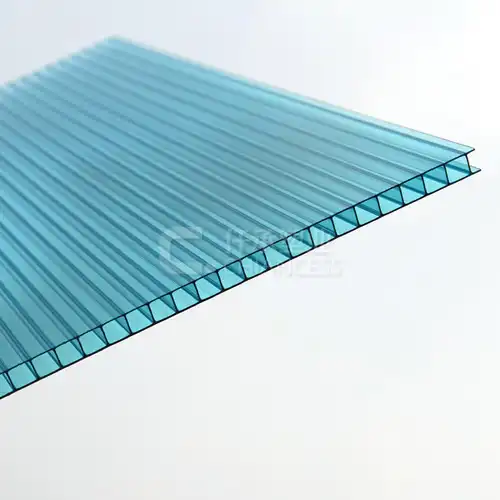

Optical Clarity: Polycarbonate honeycomb sheets are highly transparent, allowing light to pass through with minimal distortion. This makes them ideal for applications where optical clarity is essential, such as skylights, greenhouses, and architectural glazing.

Durability: Polycarbonate is a durable material that is resistant to UV radiation, weathering, and chemicals. The honeycomb structure provides additional support and protection, extending the lifespan of the sheets.

Thermal Insulation: The honeycomb structure creates pockets of air, which act as thermal insulators. This makes polycarbonate honeycomb sheets effective for reducing heat transfer, contributing to energy efficiency in buildings.

Thermal soundproofing, strength, light weight, impact resistance, optical information, durability, and durability are all incorporated in polyethylene beehive sheets, resulting in an outstanding durability and versatile polymer.They find widespread application in a variety of industries, such as manufacturing for industry, transportation, flights, and engineering.

How are Polycarbonate Honeycomb Sheets Manufactured?

2.1.Manufacturing Process

Polycarbonate honeycomb sheets are manufactured through a series of processes:

Extrusion: The polycarbonate resin is melted and extruded into a honeycomb structure using a die.

Cooling: The extruded sheet is cooled and solidified to form a rigid structure.

Cutting: The sheets are cut to the desired sizes and dimensions for various applications.

Bonding (Optional): Multiple layers of honeycomb sheets can be bonded together to achieve thicker panels with enhanced strength.

2.2.Types of Polycarbonate Honeycomb Sheets

There are different types of honeycomb polycarbonate panels based on the cell size and sheet thickness, which cater to different application needs. The cell size can vary from small to large, depending on the specific requirements of strength, weight, and light transmission.

Applications of Polycarbonate Honeycomb Sheets

Polycarbonate honeycomb sheets find applications in diverse industries due to their unique combination of properties. Here are some common applications:

3.1.Aerospace Industry

In the aerospace industry, polycarbonate honeycomb sheets are used for interior panels, aircraft flooring, and cargo containers. Their lightweight nature helps in reducing the overall weight of the aircraft while maintaining structural integrity.

3.2.Transportation Industry

In the transportation sector, these sheets are used for automotive interiors, truck bodies, and railway carriages. The lightweight yet strong characteristics of honeycomb polycarbonate sheets contribute to fuel efficiency and load-bearing capacity.

3.3.Construction and Architectural Industry

In construction, these sheets are used for skylights, roofing, and façade panels. They provide excellent thermal insulation, UV resistance, and light transmission properties, making them ideal for greenhouses and architectural glazing.

3.4.Industrial Applications

Polycarbonate honeycomb sheets are also used in industrial applications such as machine enclosures, protective barriers, and cleanroom panels. Their impact resistance and durability ensure long-term performance in demanding environments.

Advantages of Polycarbonate Honeycomb Sheets

4.1.Lightweight

Polycarbonate honeycomb sheets are significantly lighter than solid polycarbonate sheets or other materials like glass or metal, making them easier to handle and install.

4.2.High Strength-to-Weight Ratio

The honeycomb structure provides exceptional strength and rigidity while minimizing weight, making these sheets suitable for applications where both strength and weight are critical.

4.3.Thermal Insulation and UV Resistance

Polycarbonate honeycombs offer good thermal insulation properties and UV resistance, protecting against heat loss and harmful UV radiation.

4.4.Impact Resistance

Similar to solid polycarbonate sheets, honeycomb sheets exhibit high impact resistance, making them capable of withstanding hail, windblown debris, and other impacts.

Conclusion

Lastly, it ought to be mentioned that polycarbonate honeycomb sheets are extremely flexible elements with an unusual combination of beneficial characteristics, such as lightweight design, outstanding durability, effective thermal insulation, sunlight resistance, and outstanding durability against impacts.

These valuable characteristics make them an ideal choice for a diverse range of applications across various industries, from aerospace and automotive to construction and design.

Their lightweight nature ensures ease of handling and installation, while their high strength ensures durability and longevity in demanding environments. The thermal insulation properties of Honeycomb polycarbonate sheets contribute to energy efficiency, making them suitable for both residential and commercial buildings. Additionally, their UV resistance extends their lifespan by protecting them from the harmful effects of sunlight, and their impact resistance offers protection against physical stress and damage.

Given their myriad of advantages, polycarbonate honeycomb sheets present a compelling option for innovative solutions in modern engineering and design. Should you be interested in learning more about these remarkable materials or considering them for your next project, please feel free to reach out to us at simon@chiancess.com.

Our group is ready to provide you help and extensive details catered to your specific needs.

References:

Lee, K. J., & Kim, H. K. (2017). Impact behavior of honeycomb polycarbonate sheets under high-velocity impact loading. International Journal of Impact Engineering, 101, 27-35.

Gibson, L. J., & Ashby, M. F. (1997). Cellular Solids: Structure and Properties. Cambridge University Press.

Hsiao, S. W., Yang, S. Y., & Wang, L. C. (2015). Lightweight honeycomb polycarbonate panels for greenhouse applications. Construction and Building Materials, 79, 191-197.

Gao, Y., Huang, B., & Song, S. (2019). The mechanical properties and weather resistance of corrugated polypropylene boards. Polymer Composites, 40(3), 987-995.

Lee, J., & Kim, J. R. (2018). Energy absorption capability of honeycomb polycarbonate panels for impact loading. Composite Structures, 185, 156-165.

Kim, J. Y., Kim, H. S., & Lee, K. S. (2016). Environmental stress cracking resistance of polycarbonate in honeycomb panels. Polymer Testing, 54, 46-53.

.webp)