June 27, 2024

Polycarbonate solid sheets are highly versatile materials that have gained widespread recognition for their impressive combination of strength, durability, and transparency. These properties make them ideal for an array of applications across different industries. In this article, we will dive into the idea of polycarbonate strong sheets, looking at their creation, key properties, and the wide range of purposes they support. A thermoplastic polymer known for its superior impact resistance, temperature stability, and optical clarity is polycarbonate.

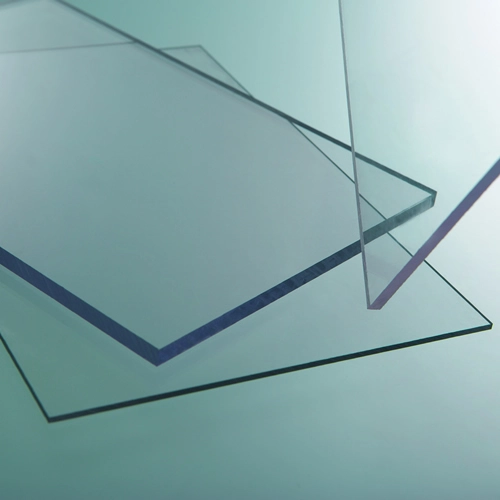

What are Polycarbonate Solid Sheets?

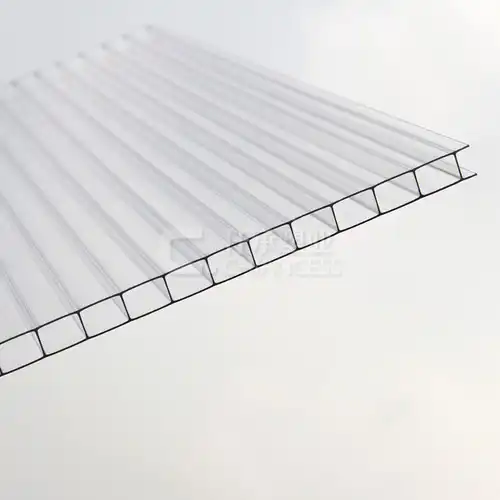

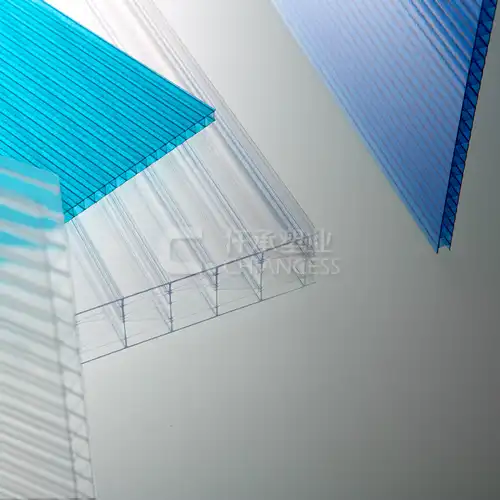

Solid polycrbonate sheets are a type of thermoplastic polymer known for their exceptional toughness and impact resistance. These sheets are manufactured from polycarbonate resin, which is a linear polymer with a unique combination of properties. They are typically produced through an extrusion process, which results in a uniform thickness and smooth surface.

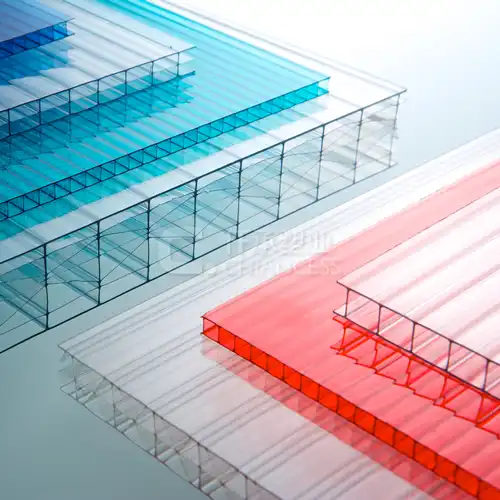

These sheets are available in various thicknesses and can be customized to meet specific application requirements. They are characterized by high optical clarity, similar to glass, but are significantly lighter and more resistant to impact. The solid structure of these sheets distinguishes them from hollow Solid polycarbonate sheets, offering additional strength and rigidity.

What are the Applications of Polycarbonate Solid Sheets?

Solid sheets made from this material offer a lightweight yet robust solution for many demanding applications. One notable feature is their ability to withstand significant physical stress without cracking or breaking, making them an excellent choice for safety and security applications.

We will explore the various sectors where they are prominently used, including construction, automotive, and industrial settings.In development, these sheets are usually utilized for material, bay windows, and coating because of their capacity to give normal light while offering unrivaled assurance against the components.In the automotive industry, they are used for vehicle windows, sunroofs, and headlight covers, contributing to passenger safety and vehicle aesthetics.

Polycarbonate solid sheets find applications across diverse industries due to their outstanding properties. Some of the common applications include:

Construction and Architecture: The products are used in construction for applications such as roofing, skylights, and canopies. Their high impact resistance and ability to withstand extreme weather conditions make them ideal for use in both residential and commercial buildings. The sheets are available in various colors and can be UV-stabilized to provide protection against harmful UV rays.

Industrial Uses: In industrial settings, The products are used for machine guards, safety shields, and sound barriers. The sheets provide protection against impact, chemicals, and debris while maintaining visibility and safety for workers.

Automotive Industry: The products are used in automotive applications for windows, windshields, and headlight covers. Their lightweight nature and high impact resistance improve fuel efficiency and vehicle safety.

Consumer Electronics: In the electronics industry, The products are used for the protection of screens and displays. Their optical clarity and scratch resistance make them suitable for applications requiring transparency and durability.

What Are the Benefits of Polycarbonate Solid Sheets?

Solid polycarbonate sheets offer several advantages over traditional materials such as glass and acrylic. Some of the key benefits include:

Impact Resistance: One of the most significant advantages of The products is their exceptional impact resistance. They are virtually unbreakable, making them a safer alternative to glass in applications where safety and durability are paramount.

Lightweight: Despite their strength, The products are lightweight, making them easier to handle and install compared to glass. This property also contributes to fuel efficiency in automotive applications.

UV Protection: The products can be UV-stabilized to block harmful UV rays. This property makes them suitable for outdoor applications without the risk of yellowing or degradation over time.

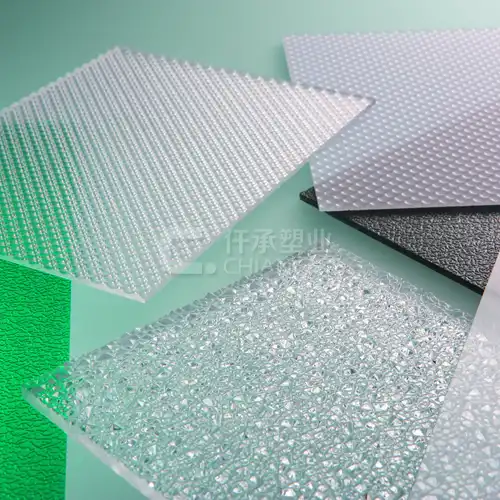

Design Flexibility: These sheets can be easily molded and fabricated into various shapes and sizes to meet specific design requirements. They are available in different colors and finishes, offering flexibility in aesthetic design.

Energy Efficiency: The products offer good thermal insulation properties, helping to reduce heating and cooling costs in buildings. They allow natural light transmission while blocking heat, making them energy-efficient materials.

Considerations for Using Polycarbonate Solid Sheets

While Solid polycrbonate sheets offer numerous benefits, there are some considerations to keep in mind:

Scratch Sensitivity: The products can be prone to scratching, especially if not treated with a scratch-resistant coating. Care should be taken during handling and cleaning to avoid abrasives that could damage the surface.

Expansion and Contraction: Like all plastics, The products expand and contract with temperature changes. Proper installation techniques, including leaving room for expansion, are necessary to prevent warping or buckling.

Cleaning and Maintenance: These sheets require regular cleaning to maintain their clarity and appearance. Mild soap and water solutions are typically recommended, avoiding harsh chemicals that could damage the material.

Conclusion

Overall, solid polycarbonate sheets are an exceptional material that combines strength, durability, and optical clarity, making them suitable for a wide range of applications across various industries. Their lightweight nature, impact resistance, and versatility in design offer significant advantages over traditional materials like glass and acrylic. By understanding their properties, benefits, and considerations, users can make informed decisions to leverage the full potential of polycarbonate solid sheets in their projects. Whether for construction, automotive, industrial, or consumer electronics, these sheets provide a reliable and efficient solution, embodying the perfect balance between form and function.

For more information about polycarbonate solid sheets and our products, please contact us at simon@chiancess.com.

References

American Plastics Council. (2020). Polycarbonate (PC) Plastic: Properties, Uses, & Structure. Retrieved from https://www.americanplasticscouncil.org.

Kuo, M. (2021). Polycarbonate: A Versatile, Strong Plastic. Retrieved from https://www.thoughtco.com.

Saeed, S. M., & Abd-El-Barr, M. M. (2020). Polycarbonate Sheets: A Comparative Review. Journal of Polymers and the Environment, 28(3), 685-699.

Ligon, S. C., & Liska, R. (2021). Polycarbonate and Poly(methyl methacrylate) (PMMA) Photopolymerizable Materials for Additive Manufacturing. ACS Applied Polymer Materials, 3(4), 1257-1269.

Foy, M. (2020). The Benefits of Using Polycarbonate. Retrieved from https://www.architectureanddesign.com.au.

Jain, S. K. (2021). Polycarbonate Sheets: Properties and Applications. Journal of Thermoplastic Composite Materials, 34(12), 1673-1694.

British Plastics Federation. (2020). Polycarbonate - The Engineering Plastic with Unique Properties. Retrieved from https://www.bpf.co.uk.

PlasticsEurope. (2021). Polycarbonate: Characteristics and Applications. Retrieved from https://www.plasticseurope.org.

National Institute of Standards and Technology (NIST). (2020). Materials Data Curation System. Retrieved from https://materialsdata.nist.gov.

International Association of Plastics Distribution. (2021). Polycarbonate Sheets: Overview, Benefits, and Applications. Retrieved from https://www.iapd.org.

.webp)