July 4, 2024

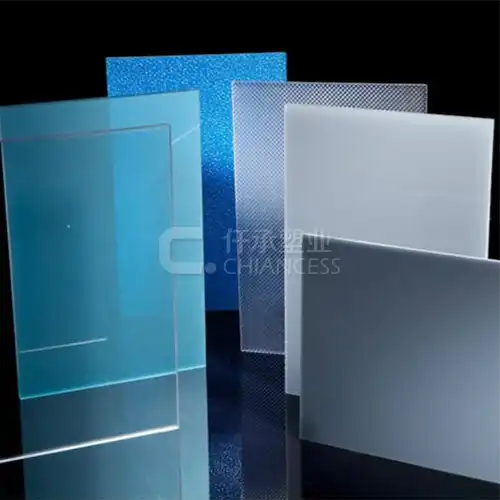

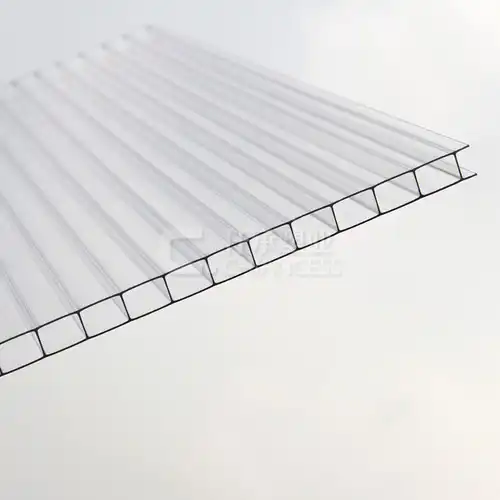

Polycarbonate is a flexible material known for its solidarity, clearness, and effect obstruction. Particularly, Clear solid polycarbonate is utilized in a wide variety of industries. In this article, we will investigate the purposes of clear polycarbonate, its advantages, and why it is liked in numerous applications.

What Are the Properties of Clear Polycarbonate?

Clear polycarbonate possesses several properties that make it suitable for diverse applications:

Polycarbonate is known for its excellent optical clarity, allowing it to transmit light effectively. This property makes clear polycarbonate an ideal substitute for glass in applications where transparency is essential.

One of the standout features of clear polycarbonate is its impact resistance, which is significantly higher than that of glass. It is virtually unbreakable and can withstand extreme weather conditions, making it a preferred choice for outdoor applications. Clear polycarbonate is lightweight, about half the weight of glass, making it easier to handle, transport, and install.

It has excellent UV resistance, which prevents yellowing and maintains optical clarity over time. This property makes clear polycarbonate suitable for outdoor applications where exposure to sunlight is common. Clear polycarbonate is easy to fabricate, can be cold-formed, and is available in various thicknesses, allowing it to be used in a wide range of applications.

Applications of Clear Polycarbonate

Clear solid polycarbonate is used in numerous industries and applications due to its unique combination of properties. Here are some common uses:

2.1. Glazing and Windows

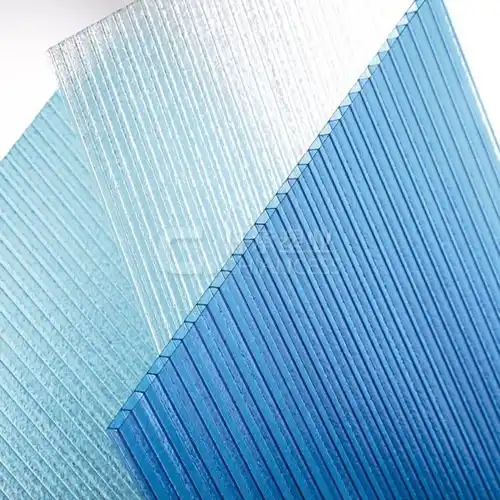

One of clear polycarbonate's primary uses is in windows and glazing, where its distinctive properties provide significant advantages over conventional glass. Due to its superior impact resistance and durability, this material is utilized extensively in both residential and commercial buildings, making it a much safer choice. In these settings, the enhanced impact resistance of polycarbonate helps protect against accidental breakage and potential injury, ensuring a safer environment for occupants. Moreover, its excellent light transmission allows for bright, naturally lit interiors, contributing to energy efficiency and comfort.

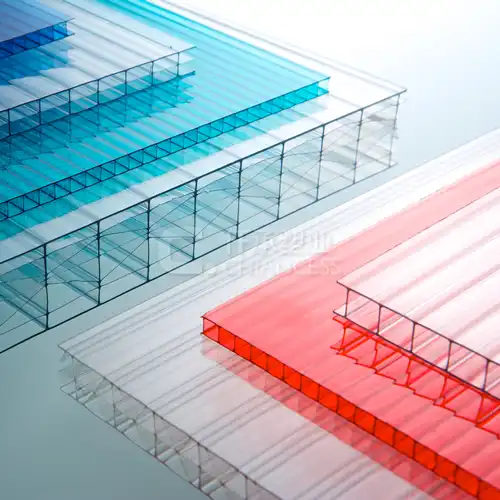

2.2. Skylights and Roofing

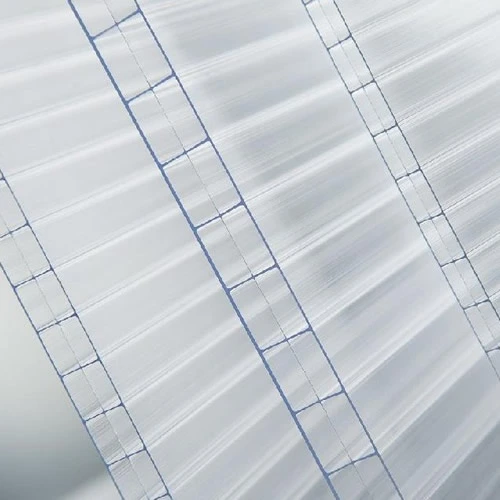

Solid clear polycarbonate sheet track down broad use in lookout windows and material applications, offering a mix of normal light transmission, strength, and effect obstruction.They are a practical choice for both residential and industrial constructions due to their light weight and ease of installation. Skylights and roofing made of clear polycarbonate sheets not only allow for a lot of natural light to enter, creating interiors that are well-lit and inviting, but they also provide a strong barrier against impact and harsh weather. Their adaptability and strength make them an appealing choice to glass, especially in settings where simplicity of establishment, life span, and wellbeing are foremost contemplations. Clear polycarbonate sheets are a dependable and effective way to create well-lit, long-lasting, and secure building environments, whether they are used in residential homes or industrial facilities.

2.3. Safety and Security

Clear polycarbonate is a preferred choice for safety applications, finding widespread use in machine guards, protective barriers, and riot shields owing to its exceptional impact resistance. This durable material serves as a reliable safeguard against various threats, including flying debris, vandalism, and forced entry attempts. Its formidable impact resistance ensures that potential hazards are effectively mitigated, making it an ideal choice for environments where safety and security are paramount. Whether in industrial settings, public spaces, or law enforcement applications, clear polycarbonate's protective properties offer peace of mind and reliable defense against a range of potential risks. With its clarity and robustness, clear polycarbonate stands as a versatile solution for fortifying safety measures and providing essential protection in diverse settings.

2.4. Eyewear

The widespread use of clear polycarbonate extends to the manufacturing of safety glasses, goggles, and prescription eyewear lenses, where its remarkable impact resistance and optical clarity render it a superior choice to traditional glass lenses. By offering a safer alternative, clear polycarbonate effectively shields the wearer's eyes from potential impacts and harmful UV radiation, ensuring essential protection in various environments. Its high impact resistance serves as a crucial safeguard, particularly in industrial settings and sports activities, where the risk of eye injury is heightened. Clear polycarbonate's versatility and protective qualities position it as an indispensable component in the production of eyewear designed to prioritize safety without compromising visual acuity or comfort.

2.5. Greenhouses

Clear polycarbonate is an excellent material for greenhouse glazing because it has numerous advantages that make it ideal for this use. Its capacity to permit most extreme light transmission guarantees that plants get adequate daylight, which is fundamental for their development and advancement. Simultaneously, clear polycarbonate offers security from hurtful UV radiation, safeguarding plants from likely harm while advancing a sound developing climate. Moreover, its lightweight nature makes it simple to deal with and introduce, working on the development interaction of nurseries. The material is flexible and easy to install because it can be cut and shaped to fit different greenhouse structures. Clear polycarbonate is an excellent choice for greenhouse glazing because of its high light transmission, UV protection, lightweight properties, and ease of customization. This makes it helpful for effective greenhouse management and plant health.

2.6. Electronic Displays

Due to their superior optical clarity, impact resistance, and scratch resistance, solid clear polycarbonate sheets are widely used in electronic displays and touch screens. Because of these characteristics, they are an excellent material for safeguarding delicate electronic components while maintaining a clear and highly visible display. The optical lucidity of clear polycarbonate takes into account sharp and energetic presentation quality, which is critical for client communication and in general gadget execution. In addition, the electronic device's integrity is safeguarded by its impressive impact resistance, which provides robust protection against accidental drops and bumps. Moreover, the scratch-safe surface keeps up with the stylish allure and usefulness of touch screens over delayed use, forestalling unattractive checks and guaranteeing a smooth, responsive client experience. With these joined benefits, clear polycarbonate sheets assume a vital part in upgrading the solidness and unwavering quality of present day electronic gadgets.

Benefits of Using Clear Polycarbonate

Using Clear solid polycarbonate offers several advantages over other materials:

3.1. Impact Resistance

Clear polycarbonate is renowned for its virtually unbreakable nature, capable of withstanding high impacts without shattering. This exceptional durability makes it an ideal choice for environments where safety is of utmost importance. Whether in industrial settings, public spaces, or personal protective equipment, the ability of clear polycarbonate to resist breaking under stress ensures enhanced safety and protection. Its resilience not only prevents injury from breakage but also provides peace of mind in high-risk areas. Consequently, clear polycarbonate is frequently chosen for applications requiring robust, reliable materials that can endure significant force without compromising on safety.

3.2. Lightweight

Clear polycarbonate offers significant advantages in terms of transportation efficiency and installation convenience due to its light weight—about half that of glass. Because shipping requires less energy and resources, polycarbonate sheets have lower transportation costs due to their lighter weight.

This benefit upgrades functional productivity as well as adds to in general cost reserve funds and further developed security estimates in development and transportation applications.

3.3. UV Resistance

Clear polycarbonate sheets offer more than just lightweight properties. They possess inherent UV inhibitors that safeguard against yellowing and degradation caused by prolonged exposure to sunlight. These built-in UV inhibitors act as a protective barrier, preventing the harmful effects of UV rays from compromising the optical clarity of the material.

This feature ensures that clear polycarbonate maintains its transparency and visual appeal over an extended period. By preserving its optical clarity, clear polycarbonate sheets are well-suited for applications that require long-term durability, such as windows, skylights, and protective barriers, where maintaining exceptional visual clarity is essential for optimal functionality and aesthetic appeal.

3.4. Design Flexibility

Cold-forming clear polycarbonate sheets into curved shapes in a variety of thicknesses gives designers a level of design flexibility that glass simply cannot match.

3.5. Energy Efficiency

Clear polycarbonate sheets give great warm protection, assisting with diminishing warming and cooling costs in structures.

Conclusion

Due to its clarity, strength, and durability, polycarbonate solid clear is a material with many applications. Whether utilized in coating, material, wellbeing hardware, eyewear, or electronic presentations, clear polycarbonate gives remarkable execution and security benefits. It is preferred by many industries due to its impact resistance, UV resistance, lightweight nature, and design adaptability.

For more information about clear polycarbonate and its applications, please contact us at simon@chiancess.com.

References

American Plastics Council. (2020). Polycarbonate (PC) Plastic: Properties, Uses, & Structure. Retrieved from https://www.americanplasticscouncil.org.

Kuo, M. (2021). Polycarbonate: A Versatile, Strong Plastic. Retrieved from https://www.thoughtco.com.

Saeed, S. M., & Abd-El-Barr, M. M. (2020). Polycarbonate Sheets: A Comparative Review. Journal of Polymers and the Environment, 28(3), 685-699.

Ligon, S. C., & Liska, R. (2021). Polycarbonate and Poly(methyl methacrylate) (PMMA) Photopolymerizable Materials for Additive Manufacturing. ACS Applied Polymer Materials, 3(4), 1257-1269.

Foy, M. (2020). The Benefits of Using Polycarbonate. Retrieved from https://www.architectureanddesign.com.au.

Jain, S. K. (2021). Polycarbonate Sheets: Properties and Applications. Journal of Thermoplastic Composite Materials, 34(12), 1673-1694.

Gao, Y., Li, R., Guo, L., & Wang, J. (2021). Performance and Properties of Polycarbonate Sheet in Greenhouse. Polymers, 13(14), 2334.

Cook, A. (2019). Polycarbonate: The Future of Transparent Plastics. Retrieved from https://www.materialstoday.com.

.webp)