July 16, 2024

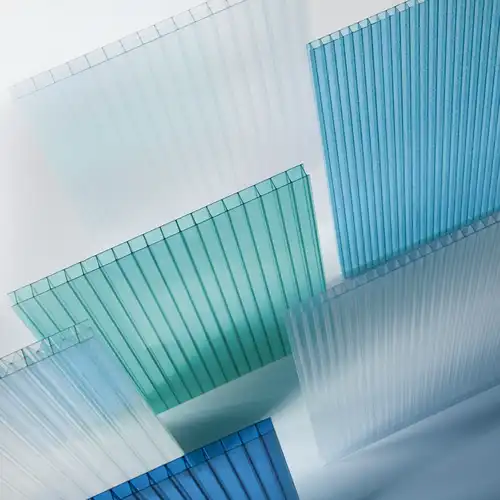

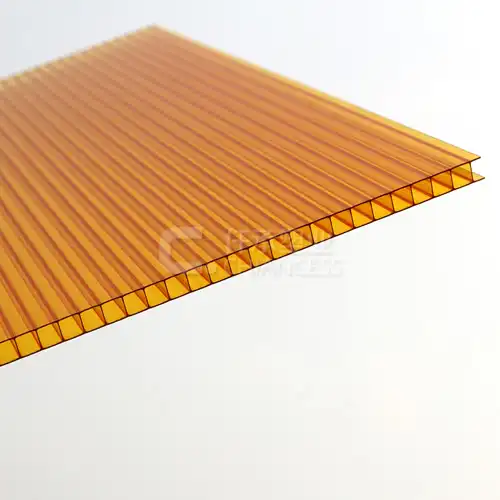

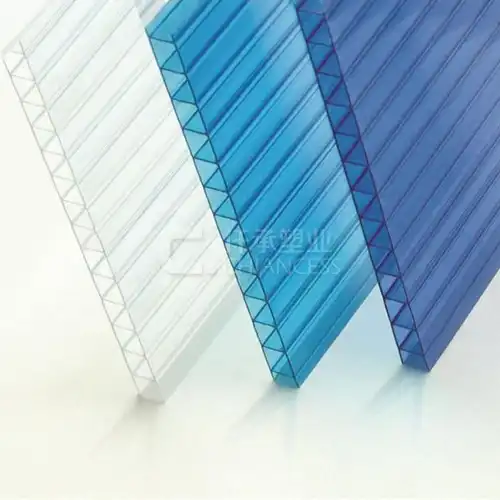

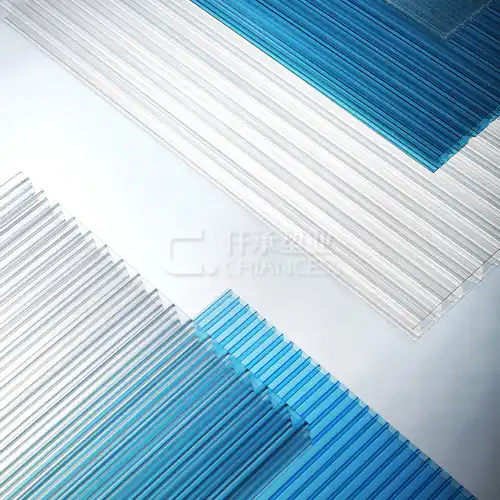

Nowadays, most businesses use empty polycarbonate because of its unusual warmth protection capabilities, lightweight construction, and robust strength. This versatile material is profoundly pursued in supportable plan drives as well as development and farming. It is lightweight while maintaining its inherent strength, making installation and handling simpler.

One of the most notable properties of hollow polycarbonate is its superior thermal insulation. In a variety of applications, these properties help effectively regulate temperatures. It is a good choice for the environment because of this feature because it is not only more energy efficient but also less expensive to heat and cool.

Because of its straightforwardness, influence obstruction, and weatherability, empty polycarbonate is regularly used in development for lookout windows, façades, and material. By allowing natural light to penetrate while shielding against UV rays and adverse weather conditions, it creates comfortable and well-lit indoor environments.

In horticulture, empty polycarbonate is utilized to fabricate nurseries since it gives establishes the best light to develop and safeguards them from outrageous climate. It will last a long time due to its durability, saving money on maintenance and increasing overall productivity.

By being recyclable and having a long life expectancy, empty polycarbonate upholds maintainable plan rehearses by bringing down how much energy utilized in structures and expanding asset effectiveness.

How is hollow polycarbonate used in construction?

In the construction industry, hollow polycarbonate sheets have received a lot of praise for their exceptional strength, transparency, and impact resistance. They are excellent choices for skylights, facades, and roofing, among other contemporary architectural designs, due to these characteristics.

Being developed, void polycarbonate sheets are routinely coordinated with different interconnected chambers, which update their fortitude as well as further foster warm insurance properties. By limiting intensity move and augmenting regular light transmission, this unmistakable plan amplifies energy productivity. Hollow polycarbonate sheets are particularly useful for greenhouses, conservatories, and industrial buildings, where it is important to maintain ideal lighting conditions without sacrificing insulation, due to this dual advantage.

Architectural and design professionals favor hollow polycarbonate due to its adaptability and ease of installation. Contrasted with heavier materials like glass, these sheets lessen the primary burden on structures, bringing down development expenses and simplifying establishment. Polycarbonate permits architectural design creativity because it can be easily shaped and curved to meet specific aesthetic and functional requirements.

Additionally, optical clarity and long-term durability are guaranteed by polycarbonate's UV resistance. This property is necessary to keep structural integrity and aesthetic appeal over time, even in harsh environments. Because it requires less frequent replacement and maintenance, hollow polycarbonate is an option for architectural applications that is both cost-effective and durable.

Due to their strength, simplicity, impact resistance, and heat protection properties, empty polycarbonate sheets have become a popular material in development. They are crucial in current design projects aimed at achieving energy productivity and stylish greatness due to their ability to improve regular light transmission and provide effective protection.

What are the applications of hollow polycarbonate in agriculture?

In agribusiness, empty polycarbonate has become crucial for establishing conditions that cultivate ideal circumstances for plant development and assurance. By providing a controlled microclimate that ensures consistent growth throughout the year, polycarbonate-sheet greenhouses demonstrate this role.

One of the essential benefits of utilizing empty polycarbonate in nurseries is its capacity to successfully adjust light dispersion and warm protection. While evenly dispersing essential wavelengths of light, these sheets enable uniform photosynthesis and healthy plant development. Additionally, polycarbonate's inherent UV protection protects crops from sunburn and other light-related harm by shielding them from harmful radiation.

Due to their weather resistance and durability, polycarbonate panels are utilized in agricultural roofing and cladding in addition to greenhouses. They endure assorted climatic circumstances, including weighty precipitation and hail, giving dependable security to horticultural designs and yields. Agricultural investments are safeguarded over the long term by this resilience, which aids in maintaining productivity.

Because it protects structures from physical damage, polycarbonate's impact resistance is especially useful in agriculture. This element lessens the gamble of breakage from hail or different effects, further improving the life span and unwavering quality of agrarian framework.

By lowering the costs of heating and cooling, hollow polycarbonate makes a significant contribution to energy efficiency. Because of its excellent thermal insulation, it helps maintain ideal growing conditions by regulating temperatures within buildings, requiring fewer external energy inputs. This brings down functional expenses as well as supports manageable practices in horticulture by lessening energy utilization and natural effect.

In outline, empty polycarbonate assumes a pivotal part in current horticulture by establishing controlled conditions that improve plant development and safeguard crops. From nurseries to horticultural material, its blend of light dispersion, UV security, influence opposition, and warm protection settles on it an optimal decision for guaranteeing efficiency and maintainability in cultivating rehearses around the world.

How does hollow polycarbonate contribute to sustainable design?

Sustainability is a key driver in contemporary design, and hollow polycarbonate aligns well with these principles. As a recyclable material, polycarbonate supports the circular economy by reducing waste and energy consumption in production processes. Its durability and long lifespan minimize the need for frequent replacements, further lowering environmental impact over time.

In architectural applications, polycarbonate's ability to enhance natural lighting reduces reliance on artificial lighting, thus decreasing energy consumption. This contributes to lower carbon footprints of buildings and supports energy-efficient design practices. The thermal insulation provided by polycarbonate panels reduces heating and cooling demands, making buildings more energy-efficient and cost-effective to operate.

Moreover, the versatility of polycarbonate allows for innovative design solutions that integrate aesthetic appeal with functional performance. Its transparency and ability to be formed into various shapes enable architects to create visually striking facades and interior spaces while maintaining environmental responsibility.

conclusion

In conclusion, hollow polycarbonate has revolutionized multiple industries with its versatile applications and sustainable attributes. Whether used in construction for enhancing natural lighting and insulation, in agriculture for creating optimal growing environments, or in sustainable design practices for reducing energy consumption, polycarbonate continues to drive innovation and efficiency. Its durability, lightweight nature, and environmental benefits position it as a material of choice for forward-thinking industries seeking to balance performance with sustainability.

If you are interested in our products or have further inquiries, please contact us at: simon@chiancess.com

.webp)