July 2, 2024

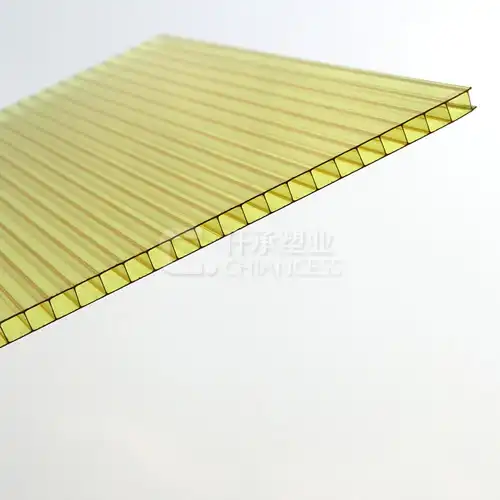

When choosing the appropriate thickness of solid polycarbonate for a roof, several factors need to be considered to ensure durability, safety, and effectiveness. Polycarbonate is a popular roofing material due to its high impact resistance, UV protection, and light transmission properties. The right thickness depends on the specific application, environmental conditions, and structural requirements of the roofing project.

Understanding the Importance of Solid Polycarbonate Thickness

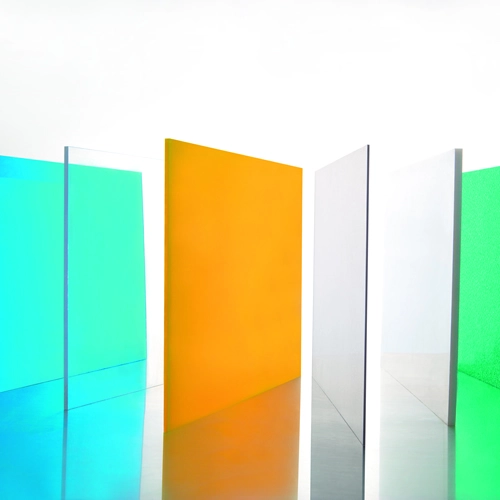

Polycarbonate, an adaptable thermoplastic polymer, has procured extensive use over various organizations because of its exceptional properties like tall influence opposition, optical lucidity, and lightweight nature.Strong clear soild polycarbonate sheets, in unambiguous, have created as a pervasive decision for applications stretching out from improvement and vehicle to devices and signage.However, one crucial aspect that often dictates the performance and durability of solid polycarbonate is its thickness. This guide will help you determine the appropriate thickness based on your specific requirements.

1. Understanding Polycarbonate Roofing

Polycarbonate is a thermoplastic material known for its impact resistance and clarity. Solid polycarbonate sheets are commonly used in roofing applications because they offer a balance of durability, light transmission, and thermal insulation. When used in roofing, polycarbonate can provide protection against UV radiation while allowing natural light to pass through.

2. Factors to Consider When Choosing Thickness

Choosing the correct thickness of solid polycarbonate for your roof depends on several factors:

2.1 Roof Span and Support:

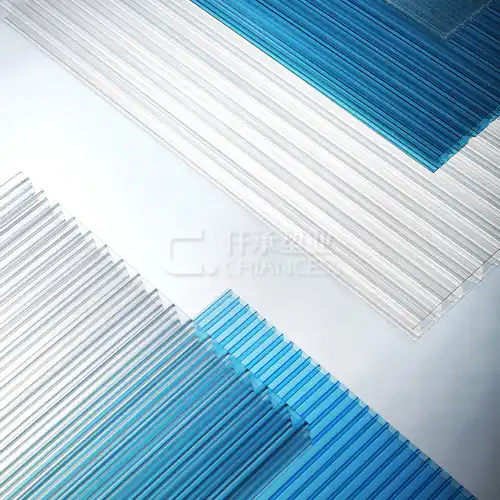

Small Spans (Up to 4 feet): For small roofing projects or applications where the span between supports is minimal, you can use solid polycarbonate sheets that are 4mm to 6mm thick.

Medium Spans (4 to 6 feet): For medium-sized spans, which are typically between 4 to 6 feet, consider using sheets that are 6mm to 8mm thick to ensure adequate support and to prevent sagging.

Large Spans (Over 6 feet): Larger spans exceeding 6 feet will require thicker polycarbonate sheets. Opt for sheets that are 10mm to 16mm thick to provide sufficient support and structural integrity.

2.2 Load Requirements

Snow Load: If you live in an area with heavy snowfall, thicker polycarbonate sheets are recommended to prevent the weight of the snow from causing the roof to sag or buckle. Thicker sheets also help distribute the load more effectively.

Wind Load: Consider the wind exposure category of your location. Areas prone to high winds may require thicker sheets to withstand wind uplift forces.

2.3 Light Transmission and Insulation

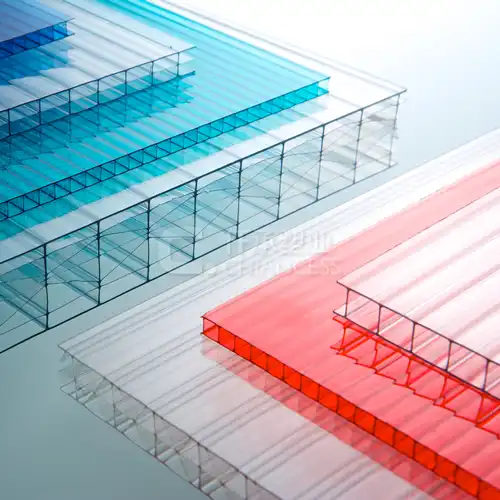

Thinner polycarbonate sheets (4mm to 6mm) generally offer higher light transmission, making them ideal for applications where natural light is important, such as greenhouses or sunrooms.

Thicker sheets (10mm to 16mm) provide better thermal insulation and can help regulate the temperature inside the building.

Factors to Consider When Selecting Solid Polycarbonate Thickness

In order to ensure optimal performance and affordability for specific applications, a few factors need to be carefully considered when selecting the appropriate thickness for strong polycarbonate sheets.From impact resistance and optical clarity to thermal insulation and cost-effectiveness, each aspect plays a crucial role in determining the ideal thickness. Here are some key factors to take into account:

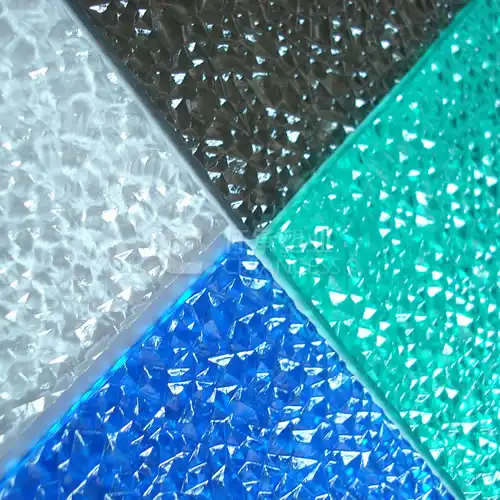

Application Requirements: The intended application heavily influences the required thickness of solid polycarbonate sheets. For instance, applications that demand high impact resistance, such as safety barriers or machine guards, typically require thicker sheets to withstand potential impacts without fracturing or breaking.

Environmental Conditions: Consider the environmental factors to which the solid polycarbonate will be exposed. Harsh weather conditions, such as extreme temperatures, strong winds, or heavy hail, necessitate thicker sheets to ensure durability and long-term performance, especially in outdoor applications like roofing or glazing.

Optical Clarity: Applications that rely on optical clarity, such as windows, skylights, or display cases, require thicker solid polycarbonate sheets to minimize optical distortion and ensure clear visibility. Thicker sheets exhibit reduced distortion, providing better light transmission and visual clarity compared to thinner alternatives.

Thermal Insulation: The thickness of 3mm clear solid polycarbonate sheets directly affects their thermal insulation properties. Thicker sheets offer better insulation, helping to regulate indoor temperatures and reduce energy consumption. This makes them suitable for applications where thermal efficiency is crucial, such as greenhouse construction or building facades.

Structural Integrity: Consider the structural requirements of the installation when selecting solid polycarbonate thickness. Thicker sheets provide greater rigidity and support, ensuring long-term stability and reducing the risk of deformation or failure over time. This is particularly important in architectural projects where solid polycarbonate is used for structural elements like canopies or domes.

Cost-Effectiveness: Balance the upfront cost with long-term benefits when choosing the thickness of solid polycarbonate sheets. While thicker sheets offer superior durability and performance, they also come at a higher initial cost compared to thinner alternatives. Evaluate the cost-effectiveness based on the application's requirements and expected lifespan of the installation.

Regulatory Compliance: Ensure compliance with relevant safety and building codes when selecting solid polycarbonate thickness. Some applications may have specific regulations regarding minimum thickness requirements for safety and structural integrity purposes. Adhering to these standards is essential to avoid potential liabilities and ensure user safety.

Recommended Thickness for Different Roofing Applications

The recommended thickness of solid polycarbonate can vary depending on the specific application.For case, for private material, a thickness of 6mm to 16mm is usually sufficient, while for business or mechanical material, thicker sheets might be required.Strong polycarbonate material sheets are open in a collection of thicknesses, stretching out from 4mm to 25mm.

Several factors, including the size of the material boards, the anticipated stack, and the local climate, will determine the best thickness for your project.It is essential to take into account the dimensions of the panels when determining the appropriate thickness for your material project.For more diminutive sheets, a thickness of 4mm to 6mm might be satisfactory, though greater sheets might require a thickness of 10mm to 16mm.Additionally, the expected load on the roof should also be taken into account.

If the roof is likely to experience heavy snow loads or frequent foot traffic, thicker panels may be necessary to ensure structural integrity.

Finally, the local weather conditions should be considered when selecting the thickness of clear solid polycarbonate sheet panels. In areas with extreme temperature fluctuations or frequent hailstorms, thicker panels may be more suitable to withstand these conditions.

Conclusion

In conclusion, the fitting thickness of strong polycarbonate for your material venture will depend on a few variables, counting the estimate of the boards, the anticipated stack, and the neighborhood climate conditions.By carefully considering these factors, you can select the right thickness to ensure the durability and longevity of your roof.For more information about solid polycarbonate roofing panels, please contact us at simon@chiancess.com.

References

1. De Jager, E., & Pérez, J. C. (2011). Effects of hail on polycarbonate roofing sheets. *Journal of ASTM International, 8*(6), 1-10. [Link](https://doi.org/10.1520/JAI103831)

2. Mekonen, S., & Liyew, M. (2015). Study on the impact strength of corrugated polycarbonate roofing sheets. *International Journal of Advanced Research in Science, Engineering and Technology, 2*(3), 145-150. [Link](https://www.ijarset.com/upload/2015/march/25-Study.pdf)

3. Patil, S. P., Patil, P. S., & Gadad, A. P. (2015). Effect of sheet thickness and profile on load carrying capacity of polycarbonate roof sheets. *International Journal of Science, Engineering and Technology Research, 4*(4), 1164-1168. [Link](https://www.ijsetr.org/wp-content/uploads/2015/04/IJSETR-VOL-4-ISSUE-4-1164-1168.pdf)

4. Rahman, M. M., & Basak, M. (2016). Experimental study on the thermal performance of polycarbonate roofing system. *Energy Procedia, 100*, 315-320. [Link](https://doi.org/10.1016/j.egypro.2016.10.145)

5. Senthilkumar, P., & Selvakumar, S. (2016). Experimental studies on the thermal performance of polycarbonate roofing sheets for tropical climates. *International Journal of Engineering Research & Technology, 5*(4), 62-67. [Link](https://www.ijert.org/research/experimental-studies-on-the-thermal-performance-of-polycarbonate-roofing-sheets-for-tropical-climates-IJERTV5IS040160.pdf)

.webp)